Different Methods Of Corrosion Prevention

Corrosion brings in safety concerns and damages the consistency of tools and similar provisions. It also leads to extra expenses, when regular maintenance is carried on. We have seen that in most of the situations, metal corrosion can be overseen, moderated, or even halted by utilizing the best possible systems. Corrosion versions can take various forms relying upon the conditions of the metal being corroded. Methods Of Corrosion Prevention can segment into 6 different groups:

- Cathodic Protection

- Coating

- Corrosion Inhibitors

- Metal Selection and Surface Conditions

- Hot-Dip Galvanization

- Plating

Read Also : How Does Oiling Prevent Rusting?

Corrosion is a serious problem faced whenever there is metal material which is placed at any location. Corrosion usually happens in metal submerged underwater or to metal which is exposed to humidity and other water sources.

Thus it is critical to use corrosion prevention methods and use Zavenir products to halt, stop and prevent corrosion in metals. The Corrosion prevention can be done through cathodic protection where through using different currents the undesirable anodic sites on a metals surface is converted to cathodic destination.

The next way is coating the metal. By using different and unique Zavenir products coating can be done on the metal and the corrosion stopped or halted. We can also use corrosion inhibitors which are chemicals which respond with metal surface or the ecological gasses causing corrosion and hence intrude on the compound response which leads to corrosion. Also, plating can be applied on the metal surface, and this one is among the best corrosion prevention methods.

By using coating, plating and Cathodic protection and also through changing the natural environment of where the metal is placed these techniques always prove to be useful whenever we want to stop or halt corrosion.

Corrosion is caused by chemical reactions amongst metal and the air in the surrounding condition. By removing the metal from, or changing, the kind of condition, metal degradation can be quickly diminished. This might be as straightforward as preventing contact with rain or seawater by putting away metal materials inside or could be as immediate control of the environment affecting the metal.

Strategies to lessen the sulphur, chloride or oxygen content in the surrounding condition can restrain the speed of metal corrosion. Plating calls for the use of electric currents to cover any surface of metal like a defensive barrier, with other metal acting as a thin layer. For instance, feed water for water boilers can be treated with conditioners or another chemical medium to alter the hardness, alkalinity or oxygen content keeping in mind the end goal to lessen corrosion on the inside of the unit.

Metal Selection and Surface Conditions

No metal is insusceptible to corrosion in all situations, yet through checking and understanding the natural conditions that are the reason for corrosion, changes to the kind of metal being utilized can also prompt noteworthy reduction in corrosion.

Metal corrosion protection statistics can be utilized as a part of the mix with data on the natural conditions to settle on choices in regards to the appropriateness of each metal.The advancement of new compounds, intended to secure against corrosion in particular situations, is always under assembly.

Monitoring of surface conditions is additionally important in shielding against metal degrading from corrosion. asperous surfaces, Cracks, or crevices whether a result of operational necessity, wear and tear, or production flaws, all can result in higher rates of corrosion.

Timely inspection and the end of superfluously exposed surface conditions, alongside finding a way to guarantee that systems are intended to keep away from receptive metal blends and that corrosion specialists are not utilized as a part of the cleaning or support of metal parts are all additionally part of successful corrosion prevention methods.

Cathodic Protection

Galvanic corrosion happens when two unique metals are placed together in a corrosive electrolyte. This is a typical issue for metals submerged together in seawater, yet can likewise happen when two unique metals are drenched in closely in soggy soils. Therefore, galvanic corrosion regularly assaults send bodies, seaward apparatuses, and oil and gas pipelines.

Cathodic protection works by changing over undesirable anodic (active) sites on a metal's surface to cathodic (passive) destinations through the utilization of a restricting current. These restricting current supplies free electrons and power nearby anodes to be spellbound to the capability of the local cathodes.

Cathodic protection can take two forms. The first is the presentation of galvanic anodes. This technique, known as a conciliatory form, utilizes metal anodes, acquainted with the electrolytic condition, to forfeit themselves (erode) so as to secure the cathode. To save metals from the harm of galvanic corrosion, cathodic protection is a proven way.

While the metal requiring protection can differ, conciliatory anodes are by and large made of zinc, aluminum, or magnesium, metals that have the most negative electron-potential. The galvanic arrangement gives an examination of the distinctive electro-potential - or integrity - of metals and amalgams.

In a conciliatory framework, metallic particles move from the anode to the cathode, which drives the anode to erode more rapidly than it generally would. Thus, the anode should routinely be supplanted. The second technique for cathodic security is alluded to as awed current protection.

This strategy, which is regularly used to ensure covered pipelines and ship bodies, requires an elective wellspring of direct electrical current to be provided to the electrolyte.

The negative terminal of the present source is associated with the metal, while the positive terminal is joined to a helper anode, which is added to finish the electrical circuit. Not at all like a galvanic (conciliatory) anode framework, in an inspired current protection framework, the helper anode isn't relinquished.

Corrosion Inhibitors

Corrosion inhibitors are chemicals that respond with the metal's surface or the ecological gasses causing corrosion, consequently, intruding on the compound response that causes corrosion. Inhibitors create a certain kind of shield against corrosion when they shape up like a thin film upon the metal's surface.

Inhibitors can work by adsorbing themselves on the metal's surface and framing a defensive film. These chemicals can be connected as an answer or as a defensive covering through scattering systems.

The inhibitors procedure of abating corrosion relies on:

- Changing the anodic or cathodic polarization conduct

- Decreasing the dispersion of particles to the metal's surface

- Increasing the electrical protection of the metal's surface

Significant end-utilized enterprises for corrosion inhibitors are oil refining, oil and gas investigation, compound generation and water treatment offices. The advantage of corrosion inhibitors is that they can be connected in-situ to metals as a remedial action to counter surprising corrosion.

Coatings

Paints and other natural coatings are utilized to shield metals from the degradative impact of ecological gasses. Corrosion can be prevented by using coatings which is counted as the simple and inexpensive approach. Coatings are assembled by the sort of polymer utilized. Regular natural coatings include: Coatings are assembled by the sort of polymer utilized.

Regular natural coatings include:

- Alkyd and epoxy ester coatings that, when air dried, advance cross-connect oxidation

- Two-part urethane coatings

- Both acrylic and epoxy polymer radiation reparable coatings

- Vinyl, acrylic or styrene polymer blend latex coatings

- Water-solvent coatings

- High-strong coatings

- Powder coatings

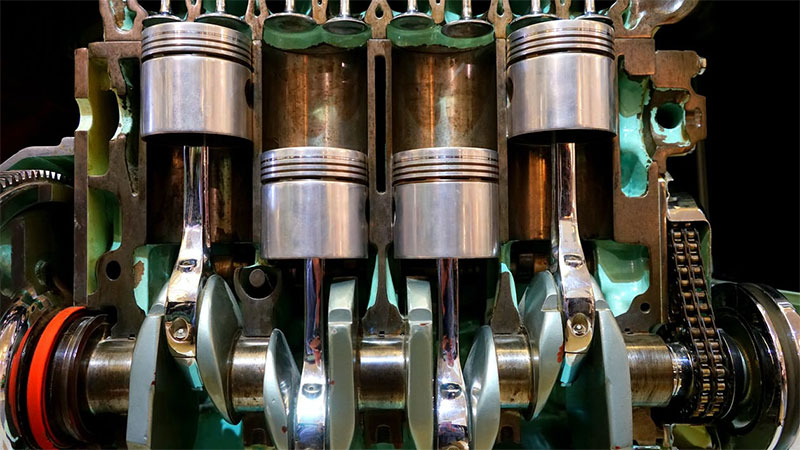

Plating Metallic coatings, or plating, can be connected to hinder corrosion and also give stylish, embellishing wraps up. There are four regular sorts of metallic coatings:

- Electroplating: A thin layer of metal - frequently nickel, tin, or chromium - is kept on the substrate metal (by and large steel) in an electrolytic shower. The electrolyte, for the most part, comprises a water arrangement containing salts of the metal to be kept.

- Mechanical plating: Metal powder can be chilly welded to a substrate metal by tumbling the part, alongside the powder and glass dabs, in a treated watery arrangement.Mechanical plating is regularly used to apply zinc or cadmium to little metal parts.

- Electroless: A covering metal, for example, cobalt or nickel, is stored on the substrate metal utilizing a synthetic response in this non-electric plating technique. Hot plunging: When submerged in a liquid shower of the defensive, covering metal a thin layer holds fast to the substrate metal.

Hot-Dip Galvanization

To keep steel from rusting, this corrosion prevention method includes dipping it into melted zinc. The iron in the steel reacts with the zinc to form a tightly linked metal covering that protects. The process has been used for more than 250 years to keep statues and playground equipment from rusting.

Unfortunately, galvanization can't be done on-site, so companies have to take equipment out of use so it can be fixed. Some tools may be too big for the process, causing companies to give up on the idea. On top of that, zinc can chip or peel. And zinc can wear down faster when it's exposed to a lot of natural elements, which means more upkeep is needed. Lastly, the zinc fumes that are released during the galvanizing process are very dangerous.

Frequently Asked Questions

What is corrosion and methods to prevent corrosion?

When some metals are exposed to wetness, acids, etc., they tarnish because of the formation of metal oxide on the surface. It's called rust. Corrosion can be prevented by painting, oiling, cleaning, galvanising, chrome plating, or making metals.

How does coating prevent corrosion

Protective coats are an easy way to stop rust by reducing the amount of time the metal spends in an area that causes corrosion. Paint is a very common way to protect something, but people also use tar, pitch, asphalt, and plastics.

What is cathodic protection of pipelines?

Cathodic protection is a popular method used in numerous industries. It uses a low electrical current to keep the metal structures away from rusting, like pipes, tanks, steel piles, and oil platforms that are out at sea.

Where are corrosion inhibitors used?

Corrosion inhibitors can be added to coolants, fuels, hydraulic fluids, engine oil, boiler water, and multiple other fluids used in industry.