METAL CLEANING

METAL CLEANING

Cleaning is an integral and critical element of the value chain within many industrial manufacturing processes be it parts or equipment. The contamination could be process oils, dirt, rust, or paints. The cleaning effect is dependent on variable factors - time, temperature, agitation, and cleaning chemical type & concentration.

Intermediate cleaning of parts is becoming more and more essential to many industrial processes, as a prelude to painting, plating, phosphating, assembly, welding, rust protection & packaging. With the new BS-VI emission norms cleaning in various technologies like LATEST SURFACTANT TECHNOLOGY in X-CLEAN™ water-based cleaners & DEAROMATIZED DEWATERING TECHNOLOGY in hydrocarbon cleaners can effectively eliminate part contamination. Maintaining an aqueous cleaner bath even at high pressure without foaming is possible with better fluid dynamics. Easing the 5S maintenance in the shop floor. The key differentiator in such cleaners is also corrosion protection properties & compatibility with part metallurgy.

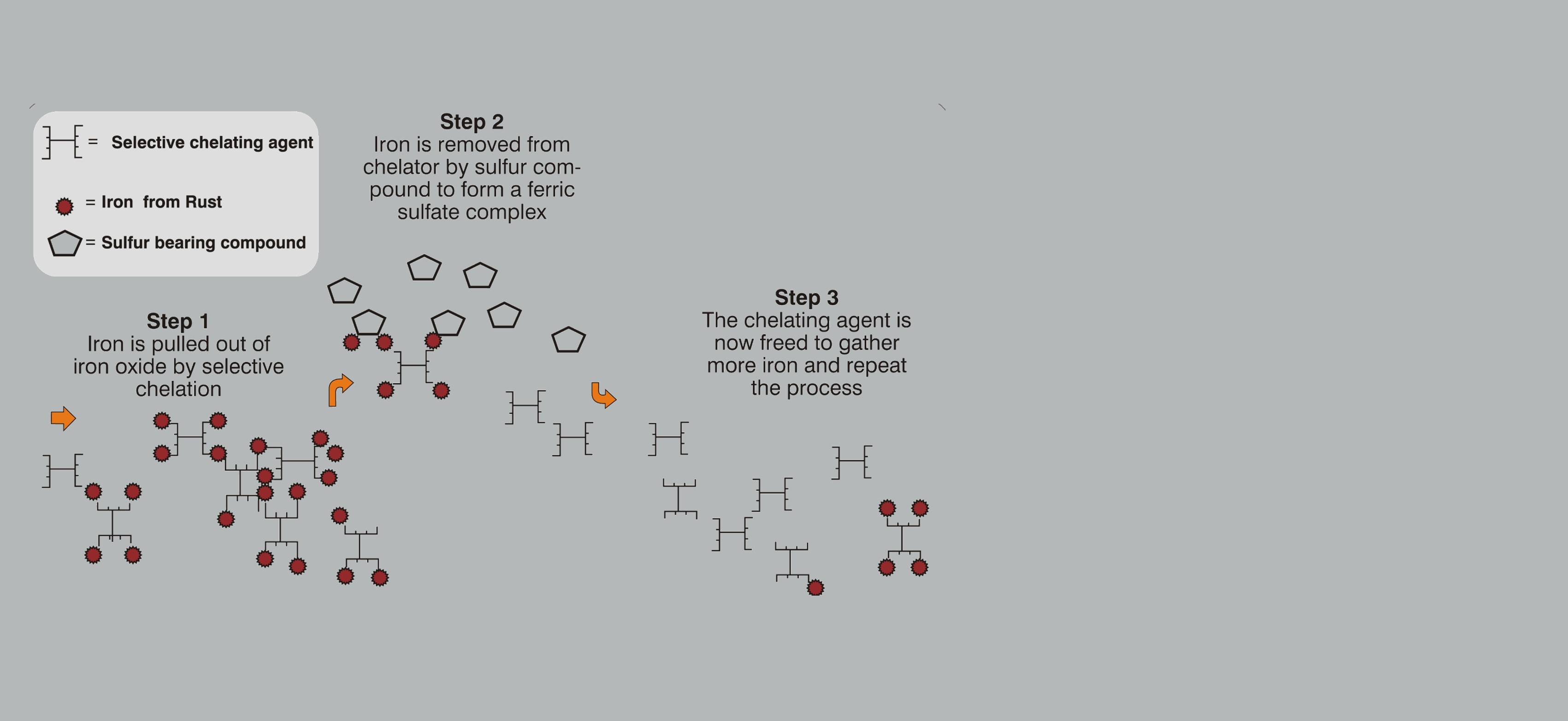

Rust cleaning or removal is a challenge across industries. Mechanical methods are labour intensive & chemical processes are usually hazardous. EHS safe and easy to use CHELATING TECHNOLOGY based RUST REVENGE® can easily remove rust by simple dipping method.

Technology

LATEST SURFACTANT TECHNOLOGY

Parts & equipment cleaning is an integral and critical element of the value chain within many industrial manufacturing processes. Conventional cleaners with basic surfactant Read More

CHELATING TECHNOLOGY

Zavenir Daubert’s motto is “prevention is better than cure”. While we encourage rust protection there are numerous cases of rusting of parts & equipment in Read More

DEAROMATIZED DEWATERING TECHNOLOGY

Moisture on the part acts as a catalyst for rust problems. Metal parts require clean and moisture-free surface before passivation. During the manufacturing, process parts go thr Read More