METAL CUTTING

METAL CUTTING

Metal cutting is the removal of material from a workpiece to produce a job. In industrial machining of metals, cooling lubricant or cutting oils are gaining a prominent role in achieving the desired output. Broadly there are two types of cutting fluids – water-soluble & neat oils. Water miscible (or soluble) are diluted with water before use and non-water miscible neat oils are ready to use. Water-soluble have a better cooling effect and are economic whereas neat cutting oils are better in lubrication and do not need much maintenance. There are further special application cooling lubricants like fully synthetic solutions and volatile minimum quantity lubricants (X-CUT®, X-HONE®, X-COOL®).

Machining of parts for automotive or consumer durables is moving towards a variety of lighter alloys which are difficult to machine. And there is high demand more precision machining with the better surface finish & stringent tolerances. Good cutting oil should assist in cutting operation with adequate tool life and surface finish at any given cutting parameters. The chemistry of cutting oil plays a major role in this aspect. Modern cutting oil technologies like GROUP II in neat oils and NANO EMULSION in water-soluble cutting oils enable high-performance machining with reduced coolant &tooling cost per component (CPC) without compromising EHS aspects.

In an era of smart manufacturing & connected enterprise, Zavenir Daubert has been at the forefront of introducing chemical management through its distinctive CHEMISTRY 4.0® program, where entire shop floor can be managed proactively reducing errors and failures.

Technology

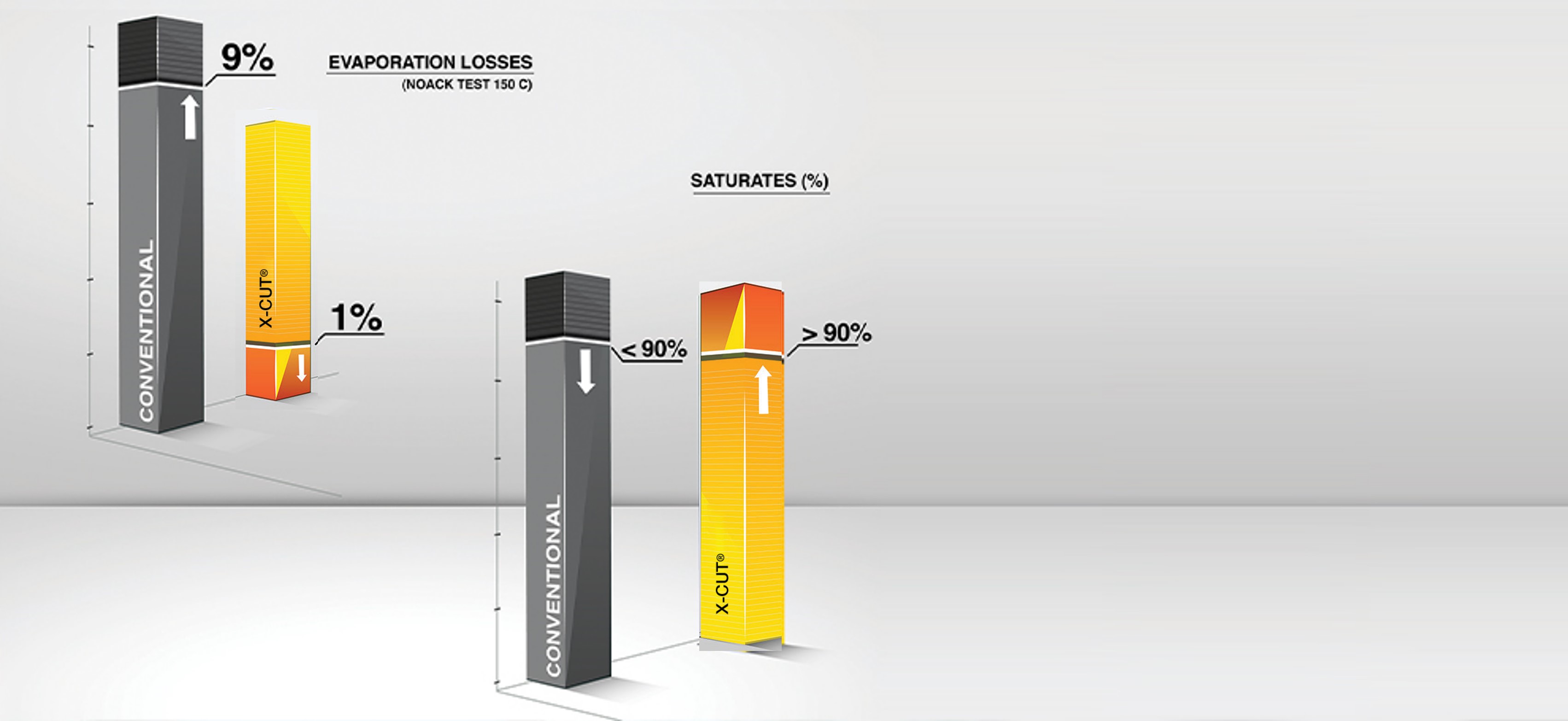

GROUP II TECHNOLOGY

Neat Cutting oils are used in various machining operations like grinding, turning, milling, broaching, drilling, tapping, and gear cutting to provide cooling and lubrication. Th Read More

NANO EMULSION TECHNOLOGY

The principal functions of water-soluble cutting fluids are cooling (dissipating heat generated in the operation), lubrication (reduce friction between the tool and the job) &am Read More