VCI PACKAGING

VCI PACKAGING

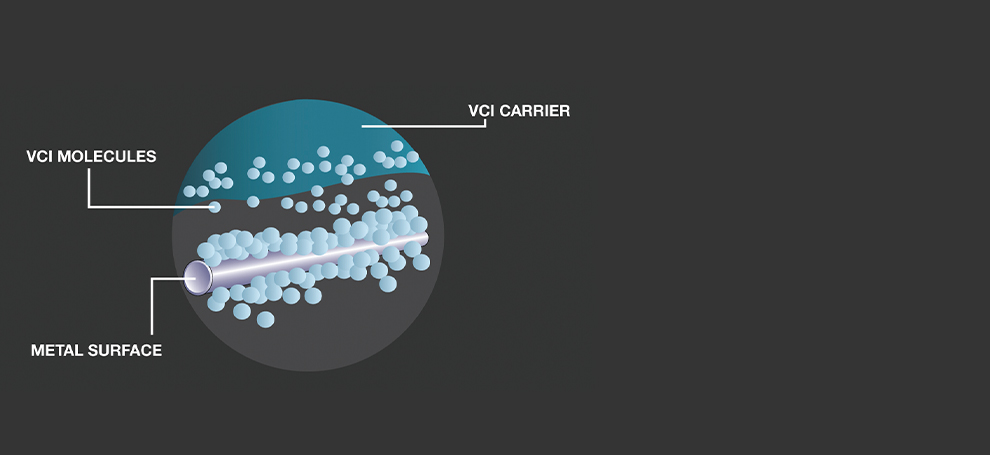

Man’s quest for protecting metals from rust without the use of greases or oils paved the way for the invention of VCI (Volatile Corrosion Inhibition). During the second world war era, VCI technology was born when George Daubert experimented with his NOX-RUST® rust preventative additives. He noticed that his tools in proximity to the rags that were soaked in this mixture remained rust-free. During World War II, the USA caught the wind of George’s corrosion solution. Daubert VCI® was then used to safely ship spare parts to troops and protect equipment and armaments in the field instead of oils and greases. Metals could now be wrapped or covered with VCI paper, and they would remain corrosion and rust-free. Also, no removal or cleaning of the invisible VCI layer was needed.

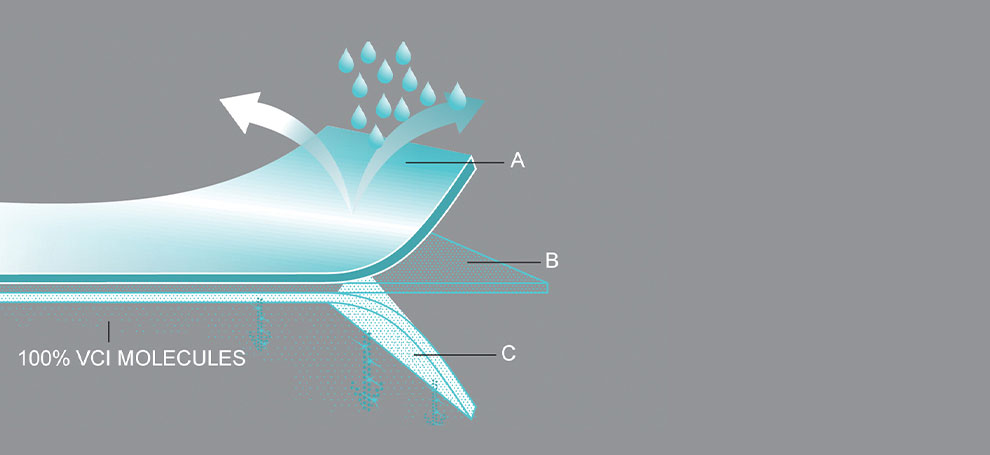

The main selection criteria for VCI usage are – Substrate metallurgy, protection duration, surface contamination, climatic conditions, size and weight of the substrate (parts), overall packaging design & cost targets. Some important considerations for products based on DAUBERT VCI® technology are Quantity of VCI (Surface Area) - VCI should be at least 1/3rd of the metal surface to be protected, Distance from Metal - Distance between metal & VCI Carrier should not exceed 300-400 mm (12-16”), VCI Access to Metal - VCI Carrier should have ‘vapor’ phase access to all surface areas required to be protected, VCI Side - Face unprinted side (coated side) to metal and Moisture Barrier - While airtight packaging is not required, suitable protection against the free flow of air depending upon climatic conditions and duration of protection is recommended. Suitable precautions also need to be taken to seal / tape adequately for both inner & out packaging.

Based on the packaging requirements, various VCI carrier variants like DAUBERT VCI® FILMS, DAUBERT VCI® PAPERS, DAUBRITE® NF VCI EMITTER CUM DESICCANT, DAUBRITE® MPI FOAM, and DAUBRITE® 5 VCI EMITTERS can be used to provide adequate cost-optimized rust protection with or without the use of RP oils. Most DAUBERT VCI® products are globally approved by OEMs & meet MIL-Spec requirements.

Technology

DAUBERT VCI® MULTILAYER TECHNOLOGY

VCI (Volatile Corrosion Inhibitors) film or VCI poly or VCI bag is increasingly becoming a popular choice of corrosion protection for exporters of metal parts due to various ben Read More

DAUBERT VCI® TECHNOLOGY

Packaging and maintenance of metal parts have always been cumbersome, owing to corrosion which to this day remains one of the major reasons to which product quality is severely Read More

DAUBERT VCI® DESICCANT TECHNOLOGY

Rusting is a phenomena caused by oxygen reacting with metal in the presence of moisture. There is a myth that adsorbing moisture alone in the enclosed space can prevent cor Read More