How Does Oiling Prevent Rusting?

Oiling Prevent Rusting: Rust has always been considered the biggest enemy of iron or iron-based industry. The most regular name for the general compound, iron oxide is rust. The process of corrosion can destroy the metal, and its value comes down to nothing. When the moisture comes in contact with the metal surface, it oxidizes and forms a coat of rust. Eventually, lead to rotting of metal and breaking it down completely.

Various traditional and modern methods are being used in various metal driven industries to prevent the process of corrosion. For example, paint coating, oiling, VCI technology, and much more chemicals. Among them, oiling is one of the best and conventional methods used to protect the metal from rust. As oil and water do not mix with each other, oiling forms a protective coating for the metal and hence prevent it from rusting. Oil can penetrate the oxide-water on the metal and stabilize it. It also goes into holes, nooks, and restricted areas on the metal and again prevents it from corrosion. But what do you do when the metal has already been corroded? Is there any way that one can save the metal from rotting away?

Today rust on iron has become very common especially in the rainy season or in places near the sea and thus oiling is critical towards preventing and curing rusting. Rusting happens because of water. It is a kind of oxidation but it can be prevented if the correct measures are taken in the correct time.

By oiling the iron rusting slows down and can be absolutely avoided as well. Moreover if the iron is submerged in water then there is a greater chance of rusting but if oiling is provided then the oil creates a protective layer over the iron and as oil and water don't mix thus the protective covering halts the rusting of the iron under water.

Thus to play safe one should regularly oil the iron as that will ensure that it is safe from rusting. If the rusting has already begun even then you can prevent further damage by oiling the rusted metal. Using the correct oil is critical for removing and stalling rusting. Thus you should go for products from Zavenir as they are the most effective and best way of avoiding and curing rusting in machinery and automobiles as well. Their products are simple to use and very effective too.

Read Also : Different Method Of Corrosion Prevention

What Damages Rusting Causes And How To Avoid Them

Rusting totally destroys the metal from inside out and outside in. It leads to corrosion and the metal equipment and machinery becomes unusable and has to be discarded with. Thus it is critical that at the right time oiling with products from Zaviner is provided so that we can arrest rusting and save the metal thus cutting down on huge costs and saving a lot of time, energy and money.

Also sometimes the rusting is so bad that the metal equipment or machinery has to be replaced and thrown away as the rusting has gone beyond the level of prevention. As they say that ' prevention is better than cure', the same is true in case of metals and using oils to control rusting.

If rusting is not prevented and dealt with it leads to:

- A lot of wastages and wastage of resources

- A lot of extra costs which might be unaffordable as the entire machine has to be replaced

- A lot of wastage of time, money and resources

- Faulty machine which leads to process breakdown

- It can also lead to dangers such as accidents

By using rust preventive oils from Zaviner these are the benefits:

- Wastage of money can be avoided

- Machines last long

- No chance of accidents and complete safety.

- No wastages of resources and time

- No process breakdown

- No need to replace machinery.

Thus it makes complete sense to use rust preventive oils which will help in avoiding rusting and will lead to long lasting machinery and saving of a lot of costs, time and resources. Moreover there will be less mishaps and there will be safety for the operations staff.

Thus if your factory has metal equipment or machinery then do go for rust preventive oils by Zavenir as they will benefit you and serve you well in the long run.

Understanding the rusting procedure

First of all, it's essential to comprehend what rust is. Put just, it's a synthetic response including iron, water and oxygen. The outcome is hydrated iron oxide, otherwise known as rust. In appearance, rust is by and large a red or yellow shade of darker, described by chipping and breaks. You'll see it on everything from bikes and Swiss armed force blades to enormous planes and tanker ships. The procedure is an outstanding case of corrosion and sees press separate amid oxidation. This is activated by dampness noticeable all around. At the point when much more water is available, the whole procedure is ultra-optimized.

Water + oxygen = inconvenience for press

As clarified above, water is the impetus that causes the oxidation procedure. Without water, oxygen can't start the oxidation procedure. This implies with a specific end goal to counteract rust, it's only a question of keeping H2O out. As oil and water don't blend, the component is a colossally powerful approach to avert oxidation. Actually, it is always excellent to apply a paint based on oil; it gets dry firmly and has no water.

At the point when metal is covered in oil it frames a defensive hindrance that prevents any outside components from leaking through. This incorporates water. As H2O can't infiltrate the metal, the rusting procedure doesn't begin. And in addition substantial water, oil likewise repulses the water that is available in oxygen. This implies notwithstanding when metal items aren't coming into coordinate contact with water, a smooth of oil can at present work ponders with regards to forestalling rust.

Inconsistent atoms

With respect to why oil and water don't blend. As a component that is less thick than water, oil dependably buoys to the surface when added to a group of H2O. Moreover, water atoms are pulled in to each other more than oil particles, which keeps the two substances from blending.

Corrosion on a business scale

In the oil and gas industry, corrosion is a genuine and ever-display issue. And additionally water harm and oxidation, destructive gasses, for example, H2S and SO2 act like significant dangers. 'High-Purity, High-Durability Sampling: Mitigating Corrosion and Maintaining Precision in the Gas Delivery System' investigates the issue in additionally detail, with a sharpened in center around the refining and petrochemical businesses. In the wake of late administrative updates as far as possible, offices are presently required to unequivocally screen outlaw outflows levels, and in addition effectively adjust explanatory frameworks with high convergences of destructive components.

Oiling Prevent Rusting: Rust Remover Oils

The answer is sure yes! In the Indian market, there are several products available to remove rust effectively from the metal surface and revive it completely. There are efficient lubricants that can scratch the rust coating from its very own root. For instance, there are oils present in the market that are safe and powerful rust and oxidation remover. Many oil-based rust removers can quickly remove the rust and corrosion from steel, cast iron, and other ferrous alloys, causing no harm to nonferrous metals such as aluminum, copper or brass and possess no danger on rubber or plastics.

The rust remover oil or rust preventive oil quickly penetrates into even the small crevices and metal pores so that it reaches to all the corroded areas of the metal. The oiling method could be effective and usually starts as quickly as 5 minutes. For such rust removing oils to show great results the metal needs to be covered all around. In light rust cases you have to immerse the ferrous object into the oil, and the corrosion starts dissolving within minutes. For severe rust cases, there is a need to immerse the corroded metal for hours to remove the rust completely. The tools which are used more often can be a good option to use rust removing oil.

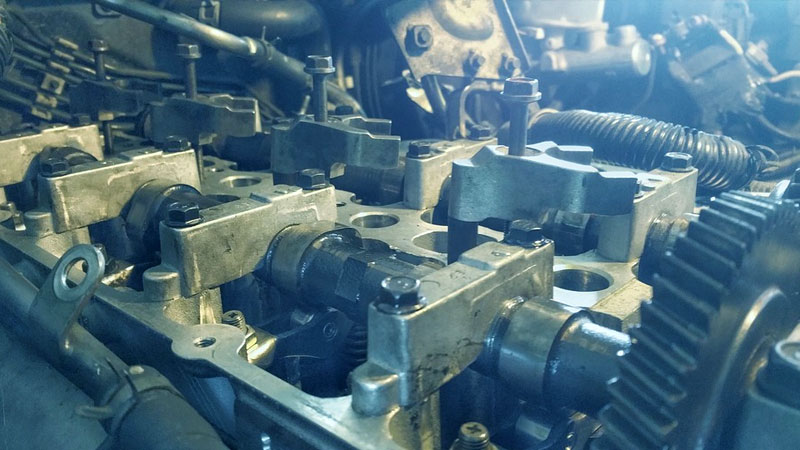

Automotive Rust Removal Treatment

Typically, in the day to day life, one has to face the problem of rusting in the automotive parts. To treat the issue of rusting and further preventing in the future, you have to follow a few instructions, which are as follows:-

- First and foremost, remove any oil, grease, and dirt present on the rusted metal.

- Remove the flakes of the rust and paint using a wire brush.

- To remove powder and soluble, rinse it with water properly. (Light rust does not get removed by simple wiping since it is firmly bonded to the metal surface.)

- The chemical or oil should be mix properly before using. For easy application, pour the chemical into a clean container.

- Brush, roll or sponge on liberally on the surface. You can use a spray application for large areas.

- Within 20 minutes or so a dark coating will appear dependent on the present temperature and humidity conditions. Apply more coats if the color is uneven. Apply second coat after 15-30 minutes for maximum protection.

- Leave it to dry for minimum 24 hours before applying a primer or a finish coat.

One can use different methods for rust treatment such as laminated rust repair using PO5 or latex coating to remove rust completely. These are safe, non-flammable and low toxic methods that not only can be used on the automotive parts but also work on pipes, valves, fences, agricultural types of equipment, frames, etc. This simple rusting removing treatment can easily restore your automobile along with saving you from a lot of expenses. Further, the treatment is the long-lasting and one-time thing.

Rust can be removed from chrome using light oils. And to remove rust from stainless steel and steel, penetrating oil is worth using.

Rust Removing Chemicals

There are varieties of superior quality rust removing chemicals which anyone can buy through online or regular retailer shop. From the elbow grease method to method of conversion, rust removing chemicals can be little tricky due to harsh to use and might release some pretty intense fumes. These powerful chemicals usually contain either phosphoric or hydrochloric acid to dissolve the rust. Apply the chemical using a paintbrush or spray cans and then scrape off the liquefied rust. Many gel formulas are also available in the market.

Using gentle chemicals like RUST REVENGE can also be another option which is a non-toxic and acid-free soaking solution for your rusted auto parts. The chemicals dissolve the rust through 'selective chelation' process. You have to pour out the solution into a tub for its easier use and immerse the object into it. These chemical removers work best for a small item, and spray remover can greatly reduce the grunt work. However, soaking chemicals are expensive and wouldn't viable for large objects. Also, the surface will be pockmarked after the process.