Appliances

Appliances

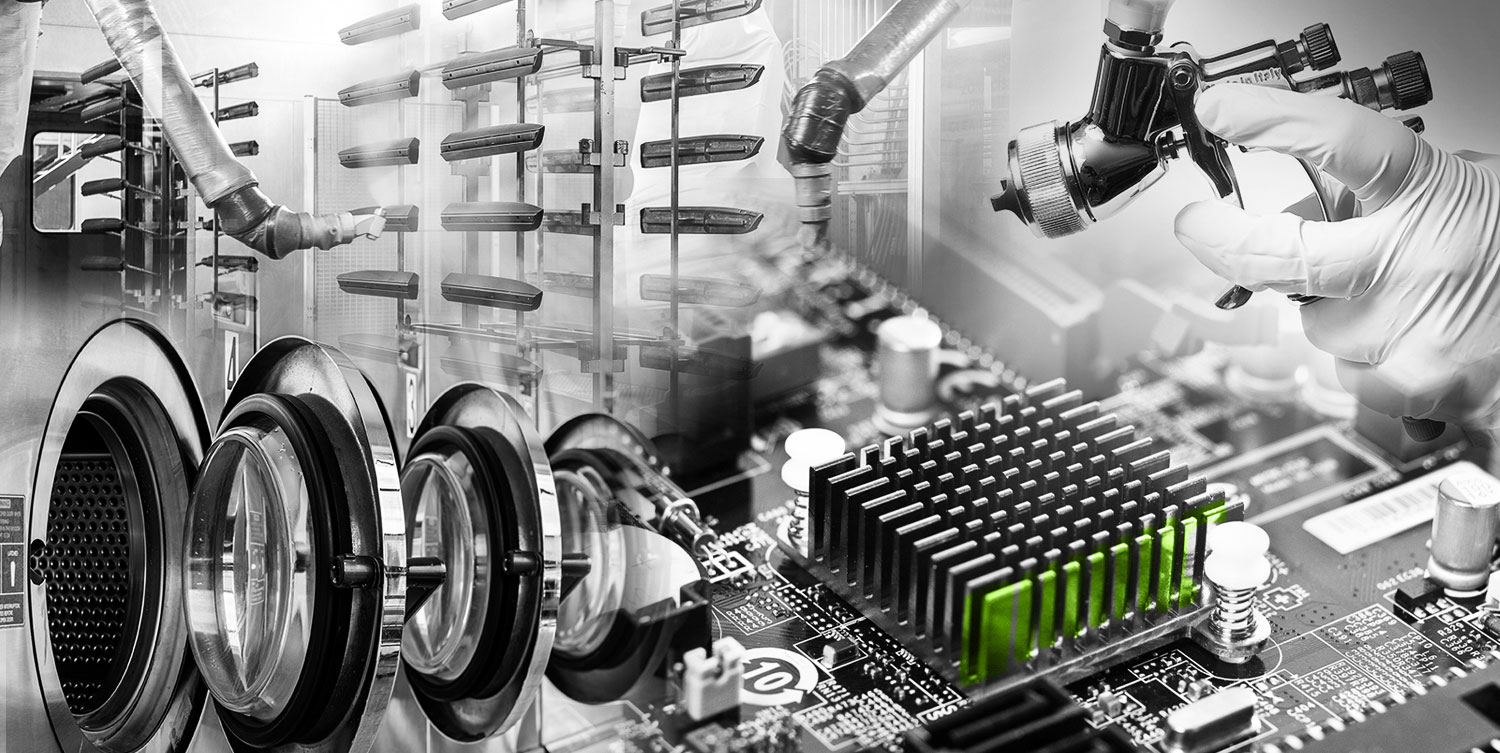

Indian appliance and consumer electronics market is expected to increase at a 9% CAGR in the coming years. Demand growth is likely to accelerate with rising disposable incomes and easy access to credit. Increasing electrification of rural areas and wide usability of online sales is also aiding growth in this demand. Covering a vast range of commercial electronics, instrumentation, networking & telecommunication systems, and medical equipment, due to adaptation of six sigma standards targeting near-zero rejection levels, manufacturers prefer usage of high-performance surface treatment and corrosion protection materials.

Introduction of VCI products in this field is also increasingly growing. Daubert VCI® technologies are used in forms of DAUBRITE® 5 VCI EMITTERS & SILVER SAVER® VCI paper for protection of plated parts, control panels etc.

Combining the properties of VCI protection with that of ESD (Electrostatic discharge) protection has set Zavenir Daubert on the right track to strengthen rust protection in this industry. PREMIUM METAL-GUARD® anti-static VCI film provides excellent corrosion protection along with protection from electrostatic discharge. This combination of technology is now being used in the field of computer and telecommunication hardware for protection of all types of metals & finishes from corrosion, especially galvanic corrosion.

Daubert's V-DAMP® sound deadeners are liquid-applied sound dampening products which are approved by several laundry appliance manufacturers.

Applications

Products

NOX-RUST®LIQUIDS

NOX-RUST® rust preventive oils are based on the CCI (Contact Corrosion Inhibition) Technology, which provides excellent corrosion protection

View ProductNOX-RUST®COATINGS

NOX-RUST® rust preventive coating is based on the SACI® Technology, which provides superior outdoor exterior corrosion protection during lay-up & mothballing

View ProductNOX-RUST®VCI LIQUIDS & POWDERS

NOX-RUST® VCI Liquids & powders are rust preventive products are based on Daubert VCI® Technology which provides continuous corrosion protection to the exposed and

View ProductDAUBERT VCI®FILMS

Daubert VCI® films are packaging films like Premium Metal-Guard® & Ferro-Film® which provide corrosion protection (up to 2 years) based on Daubert

View ProductDAUBERT VCI®PAPER

Daubert VCI® papers are packaging papers that provide corrosion protection (up to 5 years) based on Daubert VCI® Technology. These products have approvals from leading global OEMs

View ProductDAUBRITE®NF VCI EMITTER CUM DESICCANT

DAUBRITE® NF is VCI emitters cum desiccants, which provide moisture & corrosion protection (up to 2 years) in enclosed space based on advanced desiccants (moisture adsorbents)

View ProductRUST REVENGE®RUST REMOVER

RUST REVENGE® is a non-hazardous ready-to-use water-based rust remover based on chelating technology. It washes away surface rust from ferrous metals with a unique neutral pH-based solution

View ProductDAUBRITE®MPI FOAM

Flexible, non-abrasive DAUBRITE® MPI FOAM is ideal for cushioning & rust protecting electronics, sensitive subassemblies, and valuable equipment. It is based on Daubert VCI® Technology

View ProductDEWATERING FLUIDS

Zavenir Daubert Dewatering fluids are low VOC advanced dearomatized hydrocarbons for powerful cleaning of parts to remove moisture & contaminations

View ProductDAUBRITE®5 VCI EMITTERS

DAUBRITE® 5 VCI emitters are corrosion preventive devices designed to protect exposed metals inside packaging environments and enclosures. The corrosion inhibitors based on DAUBERT VCI®

View ProductX-HONE®NEAT CUTTING OILS

X-HONE® neat cutting oils are chlorine-free ready to use cooling lubrication based on Group II technology, and used in operations like Honing & Grinding operations to provide cooling and lubrication.

View ProductX-CUT®NEAT CUTTING OILS

X-CUT® neat cutting oils are ready to use cooling lubrication based on Group II technology, and used in various machining operations like grinding, turning, milling, broaching, drilling and gear cutting to provide cooling and lubrication.

View ProductX-COOL®WATER SOLUBLE CUTTING OILS

X-COOL® water soluble cutting oils are formulated based on chlorine-free extreme pressure additives, Nano Emulsion Technology

View ProductX-CLEAN™ ADVANCED AQUEOUS CLEANERS

X-CLEAN™ is a range of water-based cleaners based on Latest Surfactant Technology which can deterge both ionic or non-ionic contaminations from parts or components

View Product