Insights

All INSIGHTS

All INSIGHTS

Corrosion Protection in enclosed chamber

Today, automobiles just run the world as the world runs on them; they dominate the processes from making one’s life easy to being one of the world's largest industries by revenue. In 2020, India was the fifth-largest auto market. It was the seventh-largest manufacturer of commercial vehicles in 2019. The most prominent and highest growth achieving sector, the automotive industry, is aimed by the government to boost its capabilities and provide it with deserved global recognition. This industry comprises a wide range of companies and organizations involved in designing, developing, manufacturing, marketing, and selling motor vehicles. The complex is the process of manufacturing various parts to assemble and so on.

January 2022Keeping metals safe during monsoon

Monsoon season can bring in a higher rate of corrosion for metals and it is important to prevent them from corroding. Zavenir Daubert range of Corrosion Prevention products such as NOX-RUST® Liquids and Waxes, DAUBERT VCI® Papers & Films keep metal safe from moisture and help them perform better.

Corrosion Protection in Oil and Gas Industry

Corrosion is one of the biggest problems faced by maintenance engineers in the Oil and Gas industry and a potential hazard for production and transportation facilities. Crude oil and natural gas contain carbon dioxide (CO2), hydrogen sulfide (H2S), and free water which are inherently corrosive. Continuous extraction of CO2, H2S, and free water through oil and gas components, corrode the internal surfaces of these components and the lines and component fittings would undergo material de-gradations resulting in the loss of mechanical properties like strength, ductility, etc. which leads to the loss of materials, reduction in thickness, and at times ultimate failure. As a result of corrosion, a component may completely break down and the assembly will need to be replaced disrupting production and causing severe economic losses.

July 2021

Corrosion Protection - Automotive Industry

Corrosion is not always glaringly visible. However, just because you can't see it, does not mean that corrosion does not exist. This is demonstrated by a vehicle body. Corrosion in automotive industry is important to handle rust problem in auto industry. A Vehicle body, despite its well painted and coated exteriors, is subject to great corrosion stresses throughout, especially in areas containing body cavities, underbody, hinge and engine room areas which are subject to continual conditions of condensation, rain, mud, snow, salt and much more. Original coats of paint, however robust, fail to prevent these areas from corrosion by themselves and require additional coatings. Protecting internal metal parts of vehicles from rust and corrosion throughout extended warranties has been a challenge because of the complex geometry of vehicle parts.

July 2021

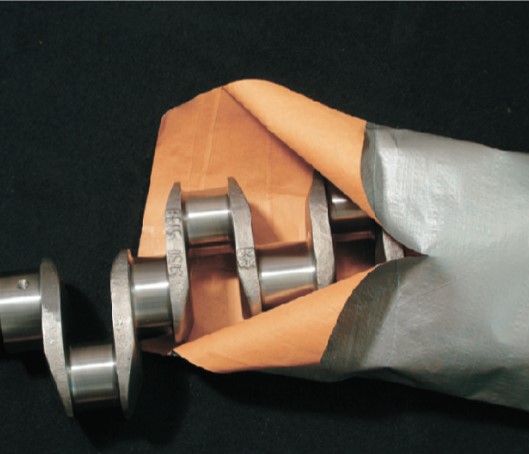

Dry Packaging - Corrosion free parts without Rust Preventive Oil

For many years, metal components are shipped across continents using a rust preventive oil often in combination with VCI packaging. It is a tried and tested method for export packaging which is considered safe, economical and is a preferred method for export shipments. However, there has been a spike in the demand for corrosion-free parts in dry packaging i.e. without Rust Preventive Oil, to reduce further complications at the receiving location as explained below.

July 2021