October 2024

October 2024A Guide to Choosing Neat Cutting Oils for Machining Process

Metal Working processes require correct cutting fluid to achieve desired part quality and productivity. While the primary benefits of MWF are efficient lubrication, heat dissipation and removal of chips from the component, the secondary benefits are more application specific like requirements of different metallurgies, quality requirements, material removal rate, application severity, operator needs etc.

Although water soluble cutting oils are applicable in most of the operations, neat cutting oils are still preferred for many applications. Wherever part quality, tool performance and corrosion protection are more important compared to heat dissipation, oil cost and part cleanliness, neat oils perform better.

Types of Neat Cutting Oils & Their Selection

Neat oils can be categorized by viscosity, by the type of base oil used and by type Extreme Pressure (EP) additive technology used.

Viscosity:

Low viscosity products offer better flushing, heat dissipation and lower drag out losses while the ones with higher viscosity provide better lubricity and better oil film strength.

- Low viscosity products (3 to 10 cst) suit less severe applications like honing & grinding whereas.

- Low viscosity products (3 to 10 cst) suit less severe applications like honing & grinding whereas.

- Mid viscosity Neat Oils (10 to 22 cst) are required for applications like Machining, Deep Hole Drilling & Broaching.

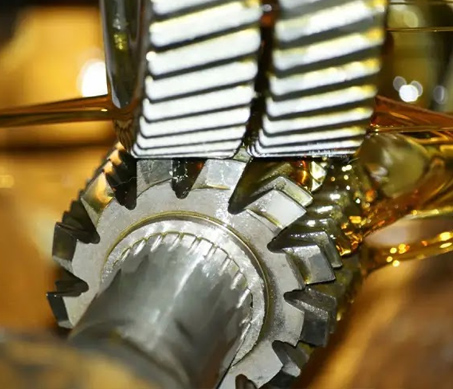

- Higher viscosities of up to 40 cst are preferred for heavier applications like Gear Hobbing, Thread rolling, heavy machining etc.

Base Oil:

- Group-1 : The products with Group-1 mineral base oils are more prone to oxidation, higher misting and evaporation.

- Group-2 & Group-3 : These are more refined and offer better resistance to oxidation and misting.

- Synthetic Base Oils : The neat oils with PAO, PAG, GTL etc. have specific benefits suited to different applications like grinding or honing like better heat dissipation, better mist indices.

- Vegetable esters : These products are not only biodegradable but also exhibit much higher lubricity, low misting and better heat dissipation compared to mineral oils.

EP Additives:

- Chlorinated Neat Oils : offer superior tool performance and they are cost efficient but they are not environment friendly.

- Non-chlorinated oils : use alternate additives like sulphur which is effective even at higher temperatures but they can corrode Copper & its alloys. Esters are good lubricity enhancers which offer ease in metal cutting and help achieve high surface quality in components.

X-Series Neat Cutting Oils

X-Series Neat Cutting Oils have a blend of high quality Group-2, Hydro-cracked base oils and premium advanced technology which ensure low evaporation & misting, efficient lubrication with high oxidation stability.

X-HONE Neat Cutting Oil with low viscosity ensures efficient cooling & flushing while their high quality EP additives ensure optimum tool performance.

X-Cut Neat Cutting Oil products are for heavier applications and focus on operational reliability and improved tool performance.

Conclusion

Selecting the right neat cutting oil is crucial for optimizing machining processes. This ensures superior tool performance, and helps achieve the desired part quality. By considering factors like viscosity, base oil type, and EP additives, manufacturers can enhance productivity and prolong tool life in their operations.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)