May 2023

May 2023Effective Rust Inhibitor Oil with Tips and Tricks

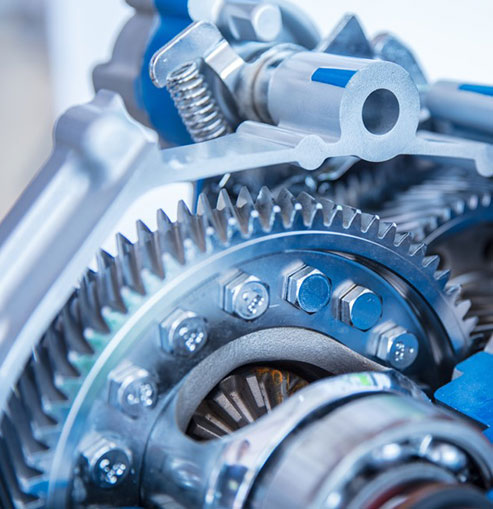

Rust inhibitor oil is a type of oil that is specifically formulated to prevent rust from forming on metal surfaces. It is a popular choice for use in industrial settings where metal parts and equipment are exposed to harsh conditions that can accelerate corrosion. It is also used in automotive applications to protect engines and other metal components from rust and corrosion. This typically contains additives that form a protective barrier on the metal surface, preventing water and oxygen from coming into contact with the metal and causing rust to form. This oil is easy to apply and can be used on a wide range of metal surfaces, making it a versatile and cost-effective solution for rust prevention.

Basis of Effectiveness of Rust Inhibitor Oil :

The effectiveness of rust inhibitor oil is based on several key factors, including the type of metal being protected, the environment in which it is used, and the specific formula of the oil.

The type of metal being protected is an important factor in determining the effectiveness of oil. Different metals have varying degrees of susceptibility to corrosion, and some require specific types for optimal protection. For example, aluminium and brass are highly susceptible to corrosion, and require specialized formulations to provide adequate protection.

The environment in which the metal is used is also a crucial factor in determining the effectiveness of rust inhibitor oil. For example, if the metal is exposed to high levels of moisture or salt, it will require a more robust solution to provide adequate protection. In addition, the temperature and pH of the environment can affect the performance of oil.

The specific formula also a critical factor in determining its effectiveness. This oil typically contains a variety of additives designed to form a protective barrier on the metal surface, preventing water and oxygen from coming into contact with the metal and causing rust to form. The quality and concentration of these additives can vary widely between different formulations, which can affect their effectiveness.

How to Maximise the effectiveness of Rust Inhibitor Oil ?

To maximize the effectiveness of oil, there are several key steps that users can take, including proper preparation of the metal surface, selecting the right type and applying it correctly.

Choose the right rust inhibitor oil for your application : There are many different types of oils available, each with its own unique composition and application method. It is important to choose the right type for your specific application to ensure that it is as effective as possible. Consider factors such as the type of metal being protected, the environment in which it will be used, and the expected level of exposure to moisture and other corrosive agents.

Prepare the surface properly : The surface should be free of dirt, oil, and any existing rust or corrosion before applying the oil. This can be achieved through a thorough cleaning process that may involve wire brushing, sandblasting, or chemical cleaning. Once the surface is clean and dry, it is ready for the application.

Apply the oil evenly and thoroughly : When applying oil, it is important to apply it evenly and thoroughly to ensure that the entire surface of the metal is covered. This can be done using a brush, spray, or immersion method, depending on the type being used and the size of the metal surface being protected.

Use the right amount : Using the right amount is important to ensure maximum effectiveness. Applying too little may not provide adequate protection while applying too much can be wasteful and may not improve the level of protection provided.

Reapply as necessary : Over time this may begin to break down or wear off, reducing its effectiveness in protecting against rust and corrosion. To ensure maximum protection, it is important to reapply rust inhibitor oil as necessary, based on the manufacturer's recommendations. This may involve periodic inspections to assess the condition of the metal surface and determine if additional oil is needed.

Monitor the effectiveness : Regular monitoring of the effectiveness of this can help identify any issues or areas where additional protection may be needed. This may involve regular inspections of the metal surface to look for signs of rust or corrosion, as well as periodic testing of the oil itself to ensure that it is still providing adequate protection.

Store rust inhibitor oil properly : To maintain its effectiveness, it should be stored properly when not in use. This may involve storing it in a cool, dry place, away from direct sunlight and other sources of heat and humidity. It is also important to ensure that the container is properly sealed to prevent contamination and maintain the quality of the oil.

Read Also : What is VCI Foam and How Does it Work for Corrosion Prevention ?

Zavenir Daubert’s NOX-RUST® Rust Inhibitor Oil :

NOX-RUST® Rust Inhibitor Oil is a high-performance oil that is designed to provide long-lasting protection against rust and corrosion on metal surfaces. It is a versatile and effective product that can be used in a wide range of industrial and commercial applications, including in the automotive, aerospace, and marine industries.

One of the key features of NOX-RUST® is its advanced formula, which contains a blend of rust inhibitors, corrosion inhibitors, and anti-oxidants. These additives work together to form a polar protective barrier on the surface of the metal, preventing moisture and other corrosive agents from penetrating the surface and causing damage.

Another important feature of NOX-RUST® Rust Inhibitor Oil is its ease of use. It can be applied using a variety of methods, including spray, brush, or immersion, and can be easily incorporated into existing maintenance routines to help prolong the life of metal parts and equipment.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)