October 2024

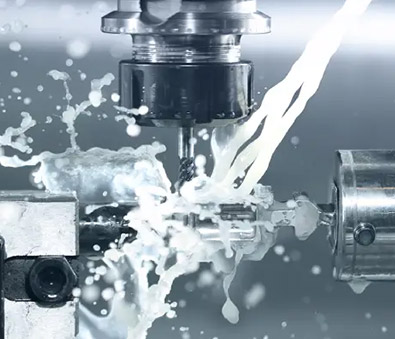

October 2024Soluble Metal Cutting Fluid Management: Strategies For Enhanced Performance

In the growing Indian economy, manufacturing has over 17% contribution and is expected to increase to 25% by the end of 2025. One of the most path breaking advances in advanced Metal cutting and processing is the use of Water Miscible Cutting Fluids for grinding to heavy machining applications and from standalone tanks to centralized sumps.

Extensive use of water soluble cutting oils has also led to focus on efficient monitoring and maintenance of metal cutting fluids. It is easier to develop a good product than to make it consistently perform over a long duration.

Well Begun Is Half Done - Sump charging

We start with correct product selection and move on to thorough sump cleaning by recommended cleaning chemicals and rinsing the system which not only disinfect the system but also help flush out the sticky residues from the system. Water parameters like total hardness, chloride hardness, conductivity and pH are to be checked before sump charging and thereafter on a weekly basis.

Top-Up & Monitoring

Concentration of oil can be checked daily by refractometer and by titration for centralized tanks on a weekly basis. Correct concentration ensures high part quality, optimum tool performance and emulsion stability. pH of cutting fluid emulsions must be between 8.5 to 9.5 to ensure optimum corrosion protection and bio-stability of cutting oils. pH should be checked at least twice a week by calibrated digital meter or precise pH paper strips. Top-ups should be done by adding a measured quantity of pre-mix emulsions to the tank which can be made manually or by jet mixers.

Crisis Management

Unfavourable conditions like pH drop, bacterial contamination or sudden WIP corrosion issue need to be tackled quickly to ensure smooth operations. Tank side additives can help to counter such issues but they must be used with caution. Like medicines, they too have side effects if used in an incorrect dosage or method.

Tramp Oil Menace

Tramp oil (Leaked hydraulic oil, slideway oil etc.) floats over the emulsion, cutting off the contact with air which can lead to microbial contamination of the fluid. Tramp oil content must be kept lower than 0.5% of emulsion volume which can be done by using skimmers. Centralized tanks can also be connected to online centrifuge filtration systems.

Importance Of Chip Removal

Metal chip/swarf accumulation in the tank weakens emulsion and initiates bacterial infection in soluble cutting oils. They can be removed by an efficient filtration system as per the material being machined and the application. Chips can be removed by vacuum suction devices to maintain sump health.

X-COOL Series: Advanced Water Soluble Metal Cutting Oils for High Performance

The X-COOL series features premium water-soluble oils formulated with superior additive technology to ensure effective pH control and concentration stability. Our technical team implements efficient coolant management practices, resulting in high part quality, reduced oil consumption, and extended sump life.

Conclusion

Effective management of water-soluble metal cutting fluids is vital for optimizing machining processes. Proper maintenance and monitoring ensure superior quality and efficiency in manufacturing operations.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)