Insights

GENERAL ARTICLES

GENERAL ARTICLES

How to Safely Store Metalworking Coolants?

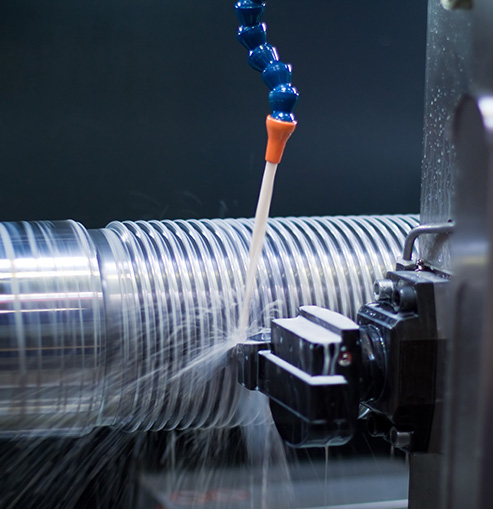

How to Safely Store Metalworking Coolants? Metalworking coolants are essential for machining-they help extend tool life, improve surface finishes, and keep operations running smoothly. However, improper storage can lead to contamination, reduced performance, and even safety hazards. To get the most out of these fluids make sure to store them in a safe workspace. Also, it is important to follow proper storage guidelines listed by the manufacturer. Importance of Proper Storage Techniques Proper storage techniques are the need of the hour since they help you save your investment by improving the overall life of the metalworking coolants. Here are a few notable benefits: Prevents Contamination: When you store the coolants properly and keep them free from dust, dirt, and other impurities, it overall improves the performance of the coolants. Following Safety Compliance: Following storage guidelines helps meet safety regulations that reduce risks from spills or leaks. Saves Money: When you store the cutting oils properly, it extends the life of cutting oils. It prevents waste and reduces costs. Protects the Environment: Safe storage minimizes the risk of leaks and spills that could harm the environment. Improves Efficiency: Storing coolants correctly makes them easier to access and manage, so you always have what you need when you need it. Improve Workplace Safety: A well-organized storage area reduces the risk of spills, accidents, and injuries. How to Store Metalworking Coolants Safely? Keep it Cool & Dry: Store coolants in a temperature-controlled environment to prevent them from breaking down. Check the product’s technical datasheet for ideal storage conditions. Use the Right Containers: Always store coolants in their original, sealed containers or certified storage vessels to prevent leaks and contamination. Label Everything: Clearly mark all containers with product names, batch numbers, and expiration dates for easy identification. Maintain Proper Ventilation: Store coolants in a well-ventilated area to prevent the buildup of harmful vapors. Also, take care of the fire safety. Have Spill Kits Ready: Keep spill kits nearby to quickly respond to leaks or spills. Follow FIFO (First In, First Out): Use older stock first to prevent coolants from expiring without being used. This can increase the wastage. Inspect Regularly: Check storage areas for leaks, damage, or expired products to make sure of safety. Control Humidity: Keep humidity levels low to prevent microbial growth in water-based coolants. Common Mistakes to Avoid Ignoring Expiration Dates: Expired coolants can lead to machining issues - always check and dispose of the outdated products properly. Leaving Containers Open: Make sure that the containers in which you store the coolants are properly sealed. Make sure lids are always secure. Store in Direct Sunlight: Heat and UV exposure degrade coolant quality to a certain extent. Thus keep them in a cool or shaded area. Don‘t Mix Different Products: Combining different coolants can cause unwanted chemical reactions. Thus, always store them separately for safety purposes. Neglecting Safety Data Sheets (SDS): SDS documents provide critical storage and handling information. Always refer to them for the storage guidelines. Ignoring Regulations: Failing to follow local storage laws can result in fines and safety risks-stay informed. Skipping Employee Training: Always train the workers/employees about handling the products. Untrained staff increases the risk of spills, contamination, and improper storage. Conduct regular training sessions to have high safety standards within your organization. You can extend the life of your metalworking coolants, reduce costs, and ensure a safer workspace by following the proper storage guidelines, and avoiding common mistakes. Proper storage isn't just about organization. It’s about protecting your investment and maintaining efficiency in your operations. Storage of Zavenir Daubert’s X-COOL®, X-CUT® Products X-COOL & X-CUT series of high-performance Metal Working Fluids by Zavenir Daubert improve component quality and productivity while making sure of operator and process safety. For storing these products you should maintain similar guidelines as storing other coolants. Store them in a cool and dry place, keep them in separate containers, and label them properly. Also, make sure that they are used before expiring. Conclusion By following proper storage practices, you can extend the life of your metalworking coolants, reduce costs, and maintain a safe, efficient workspace. Investing in safe storage today ensures better performance and fewer risks in the long run.

March 2025

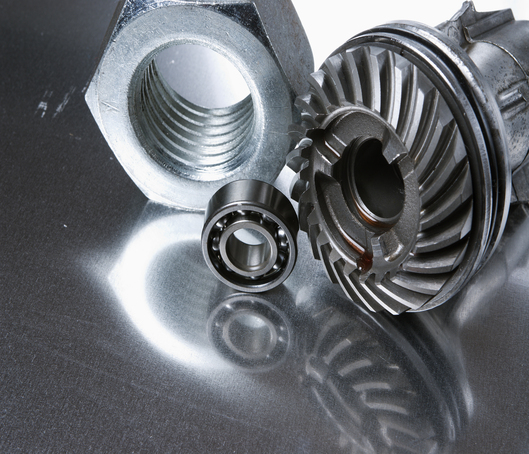

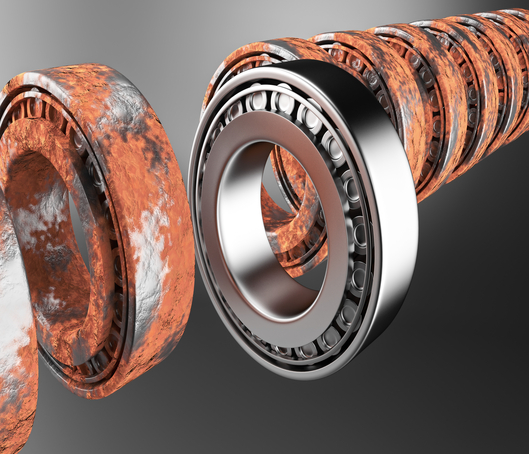

How Industrial Rust Remover Can Save Your Metals

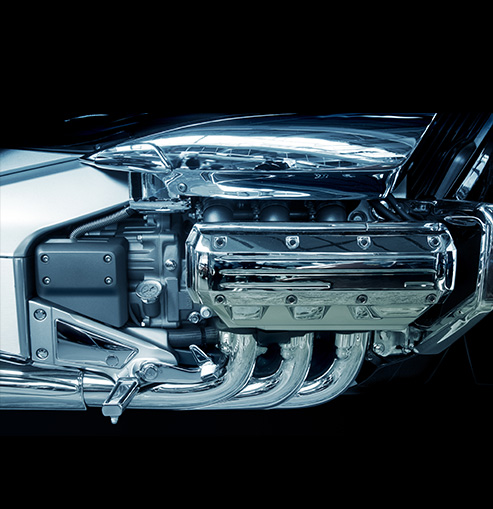

How Industrial Rust Remover Can Save Your Metals? Industrial rust removers are designed to eliminate rust from metal surfaces. These chemicals work by either dissolving the rust or converting it into a stable compound. Acid-based chemicals like hydrochloric and phosphoric acids are effective but can be harsh on metals. Chelating agents and neutral pH solutions are gentler and eco-friendly. Rust removers come in various forms, including liquids, gels, and sprays, and are used across industries such as automotive, manufacturing, and metalworking. Selecting the right chemical depends on the extent of rust, surface type, and safety considerations. Types of Industrial Rust Remover and How They Work? 1. Rust Removers based on Acids: A strong acid that reacts with rust and dissolves it. They can help remove the rust at a high speed and can clean highly rusted surfaces but they can also be corrosive to the component if left in contact for long duration. They need to be used with adequate safety precautions as they may act as an irritant to the skin and respiratory system. 2. Chelating Agents: They bind to rust molecules and pull them away without damaging the metal surface. They are milder on metals and are safe to use but the application time may be comparatively higher than acidic products. 3. pH Neutral products: A neutral pH rust remover reacts with rust without damaging the component. These are applicable on ferrous and non-ferrous metals. They are non-corrosive and safer to use, thus minimizing risk to users and the environment. The application time required for removal of heavy rust may be higher. 4. Rust Converters: They convert rust into a stable surface which can be used for coating or painting processes. They create a protective layer over the rusted metal and offer corrosion protection by creating a protective layer over the treated area. They may not be able to remove heavy rust. 5. Solvent-Based Rust Removers: They help to dissolve light rust and surface impurities like dirt or grease making the surface cleaner. They cannot remove heavy rust; they pose the risk of catching fire and thus require adequate ventilation during use. 6. Electrolytic Rust Removal: This process involves dipping the rusted part in a solution and electrical current is used to convert the rust back into its original form by electrolysis. Highly effective for heavy rust removal and can restore items without damaging the surface but they require special equipment and take more time for component restoration. What are Strong Rust Removers? Are they safe in use? Strong Rust Removers generally have acids such as Hydrochloric Acid and Phosphoric Acid. They remove rust very fast, they are useful in removing heavy rust, but they are corrosive to both metal and human skin and hence, they require careful handling with protective equipment. Therefore, it is always recommended to use personal protective equipment (PPE) like gloves, goggles, and masks. These products must be used in well-ventilated areas, and the component surface must be rinsed well afterward to prevent it from rusting again. Which Rust Removal Chemical Should We Use? To ensure effective removal of rust and also keeping in mind safety & ease of use, we should select a product that is environmentally friendly, has a neutral pH, and it has chemicals which are not corrosive in nature. The choice of rust remover, however, ultimately depends on the specific needs of the task, taking into consideration factors such as the type of metal, the severity of the rust, and any safety concerns. This balanced approach allows for efficient rust removal without compromising the integrity of the metal or the safety of users and the environment. Zavenir Daubert’s Effective and Eco-Friendly Rust Remover - Rust Revenge® Zavenir Daubert’s Rust Revenge is a safe and effective rust remover that tackles rust and corrosion without harmful chemicals. It not only removes rust quickly but also protects surfaces from future damage that makes it a great choice for anyone looking to maintain their equipment while being kind to the environment. Below are a few key features of Rust Revenge® 1. Water-Based, Neutral pH and Acid-Free: Rust Revenge® is a water-based formula that eliminates the need for harsh chemicals. The neutral pH and absence of acids make it safe for use on a wide variety of metals without corroding or damaging them. 2. Non-Hazardous and Non-Corrosive: Safe for users and metal surfaces, it does not emit harmful fumes or cause skin irritation. 3. Non-Toxic and Non-Flammable: Safe to handle and store, posing no fire or health risks. 4. Easy Disposal, Biodegradable and Eco-Friendly: The formula is environmentally friendly and biodegradable nature ensures simple and safe disposal practices. 5. Fast-Acting and Safe for non-rusted Metals: Delivers quick rust removal while maintaining the integrity of non-rusted metals. Unlike strong acids, it will not harm non-rusted surfaces. 6. Reusable: Rust Revenge® can be reused up-to few times, making it a cost-effective solution. Conclusion Zavenir Daubert’s Rust Revenge® offers an effective and eco-friendly solution for rust removal that prioritizes safety and sustainability. With its fast-acting formula and gentle approach, it's the ideal choice for preserving metal integrity while minimizing environmental impact.

October 2024

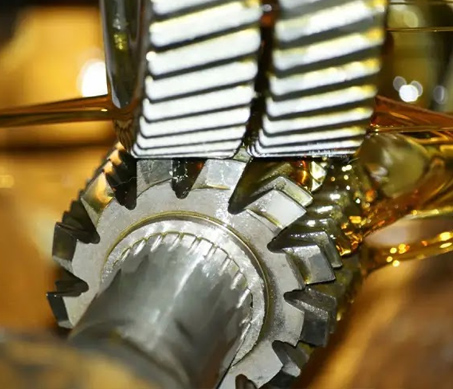

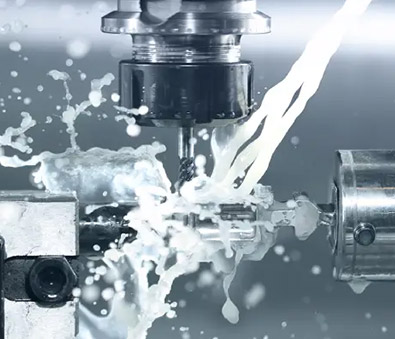

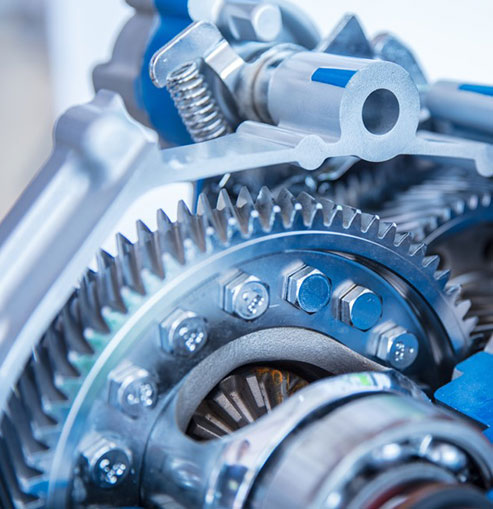

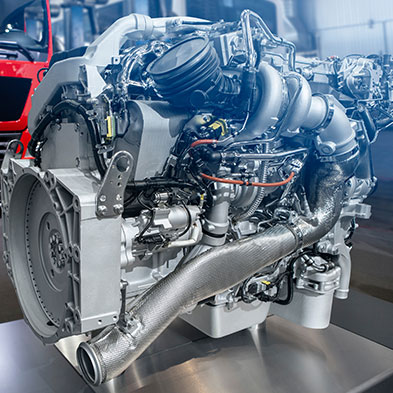

Purpose, Uses and Application of Water Soluble Cutting Oil

Purpose, Uses and Application of Water Soluble Cutting Oil Water soluble cutting oil is used to improve the metalworking operations by providing cooling and lubrication during numerous machining processes. It dissipates heat that is generated during cutting. This prevents tool wear, improves surface finishing, and minimizes corrosion on machined parts. These water soluble cutting oils form a stable emulsion when mixed with water. This helps in effective heat dissipation, smooth machining, and reduced friction. They help in chip removal, preventing material build-up on tools and maintaining precision during operations. This makes them essential for machining operations that involve ferrous and non-ferrous metals across various industries. Purpose of Water Soluble Cutting Oil Cooling and Lubrication: These oils dissipate heat generated during machining to provide lubrication between the tool and workpiece which extends tool life and improves surface finish. Corrosion Protection: These oils contain additives that protect machined parts and equipment from rust and corrosion, even in the presence of water. Chip Removal: It helps in removal of metal chips and debris that ensures a clean work area and prevents chips from affecting the precision of the operation. Emulsion Stability: These water soluble metalworking oils form a stable and long-lasting emulsion when mixed with water. This emulsion helps maintain consistent lubrication and cooling throughout the metalworking process. Environmental Benefits: Since these oils are water-based, they are more eco-friendly and offer easier disposal and lower environmental impact compared to petroleum-based oils. Versatility: These water based cutting oils are suitable for use in various machining operations, including milling, turning, drilling, grinding, and tapping. These many usages make these oils ideal for various industries. Uses of Water Soluble Cutting Oil Metalworking: These oils are widely used in various metal cutting processes such as turning, milling, drilling, grinding, etc. to cool and lubricate the tool and workpiece. Automotive Industry: These are used in the machining of engine components, transmission parts, and other precision metal components that require high tolerance levels. Aerospace: Used in machining high-performance alloys for aerospace applications, ensuring precise cutting and reducing wear on expensive cutting tools. Heavy Machinery: The water based oils are essential in the production of large-scale machinery parts, such as gearboxes, turbines, and hydraulic systems, where consistent performance is needed. Tool Manufacturing: Applied in the grinding and sharpening of cutting tools to maintain accuracy and prevent tool degradation. Die and Mold Cutting: Essential in cutting and shaping molds and dies, providing excellent lubrication and heat dissipation for precision in fine cutting. Applications of Water Soluble Cutting Oil Machining of Ferrous and Non-Ferrous Metals: Suitable for a wide range of metals including steel, aluminium, copper, titanium alloys, etc. Milling: Supports high-speed milling operations by maintaining stable temperatures and reducing friction between the tool and the workpiece. Drilling and Tapping: Offers excellent performance in drilling and tapping operations by reducing tool wear and improving chip evacuation. Grinding Operations Used in surface, cylindrical, and centerless grinding operations where temperature control and surface finish are vital. Broaching: Ensures smooth broaching operations, minimizing the risk of tool breakage and ensuring precision in the removal of material. Sawing and Cutting: Used in sawing and cutting applications to boost cutting speed, reduce heat, and extend tool life. Zavenir Daubert’s X-COOL® Water-Soluble Cutting Oil Zavenir Daubert’s X-Cool Water soluble cutting oil based on Nano-emulsion technology stands out in the market of water based cutting oil for machining processes. Below are some of the notable features of the X-Cool Cutting Oil. Advanced Cooling: X-COOL® provides superior cooling capabilities, designed specifically for high-speed machining processes that require excellent thermal control. Lubrication Efficiency: It ensures efficient lubrication between cutting tools and workpieces, reducing friction and extending the life of cutting tools. Rust and Corrosion Protection: Contains state-of-the-art additives that protect metal surfaces from oxidation, ensuring no rust or corrosion forms on the machined parts. Environmentally Friendly: These Boron free products are environmentally safe, making it a preferred choice for sustainable manufacturing operations. Stable Emulsion: X-COOL® forms a long-lasting, stable emulsion with water, reducing the need for frequent oil changes and ensuring consistent performance throughout its use. Versatile Use: Suitable for a wide range of metalworking applications including turning, milling, drilling, and grinding across multiple industries. Economical: Designed to reduce operational costs by minimizing tool wear, decreasing downtime for tool changes, and optimizing coolant usage. Compatibility: Works effectively with both ferrous and non-ferrous metals, making it a versatile solution for various metal machining operations. Conclusion Water soluble cutting oils are important for improving efficiency, precision, and tool longevity in metalworking processes. Their versatility and eco-friendly properties make them a preferred choice across industries for machining both ferrous and non-ferrous metals.

October 2024

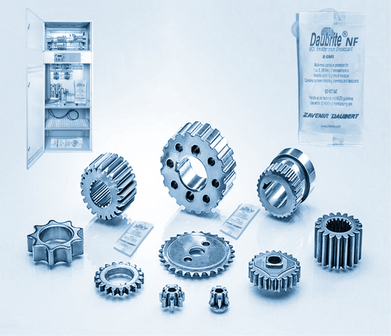

A Guide to Choosing Neat Cutting Oils for Machining Process

A Guide to Choosing Neat Cutting Oils for Machining Process Metal Working processes require correct cutting fluid to achieve desired part quality and productivity. While the primary benefits of MWF are efficient lubrication, heat dissipation and removal of chips from the component, the secondary benefits are more application specific like requirements of different metallurgies, quality requirements, material removal rate, application severity, operator needs etc. Although water soluble cutting oils are applicable in most of the operations, neat cutting oils are still preferred for many applications. Wherever part quality, tool performance and corrosion protection are more important compared to heat dissipation, oil cost and part cleanliness, neat oils perform better. Types of Neat Cutting Oils & Their Selection Neat oils can be categorized by viscosity, by the type of base oil used and by type Extreme Pressure (EP) additive technology used. Viscosity: Low viscosity products offer better flushing, heat dissipation and lower drag out losses while the ones with higher viscosity provide better lubricity and better oil film strength. Low viscosity products (3 to 10 cst) suit less severe applications like honing & grinding whereas. Low viscosity products (3 to 10 cst) suit less severe applications like honing & grinding whereas. Mid viscosity Neat Oils (10 to 22 cst) are required for applications like Machining, Deep Hole Drilling & Broaching. Higher viscosities of up to 40 cst are preferred for heavier applications like Gear Hobbing, Thread rolling, heavy machining etc. Base Oil: Group-1 : The products with Group-1 mineral base oils are more prone to oxidation, higher misting and evaporation. Group-2 & Group-3 : These are more refined and offer better resistance to oxidation and misting. Synthetic Base Oils : The neat oils with PAO, PAG, GTL etc. have specific benefits suited to different applications like grinding or honing like better heat dissipation, better mist indices. Vegetable esters : These products are not only biodegradable but also exhibit much higher lubricity, low misting and better heat dissipation compared to mineral oils. EP Additives: Chlorinated Neat Oils : offer superior tool performance and they are cost efficient but they are not environment friendly. Non-chlorinated oils : use alternate additives like sulphur which is effective even at higher temperatures but they can corrode Copper & its alloys. Esters are good lubricity enhancers which offer ease in metal cutting and help achieve high surface quality in components. X-Series Neat Cutting Oils X-Series Neat Cutting Oils have a blend of high quality Group-2, Hydro-cracked base oils and premium advanced technology which ensure low evaporation & misting, efficient lubrication with high oxidation stability. X-HONE Neat Cutting Oil with low viscosity ensures efficient cooling & flushing while their high quality EP additives ensure optimum tool performance. X-Cut Neat Cutting Oil products are for heavier applications and focus on operational reliability and improved tool performance. Conclusion Selecting the right neat cutting oil is crucial for optimizing machining processes. This ensures superior tool performance, and helps achieve the desired part quality. By considering factors like viscosity, base oil type, and EP additives, manufacturers can enhance productivity and prolong tool life in their operations.

October 2024

Soluble Metal Cutting Fluid Management: Strategies For Enhanced Performance

Soluble Metal Cutting Fluid Management: Strategies For Enhanced Performance In the growing Indian economy, manufacturing has over 17% contribution and is expected to increase to 25% by the end of 2025. One of the most path breaking advances in advanced Metal cutting and processing is the use of Water Miscible Cutting Fluids for grinding to heavy machining applications and from standalone tanks to centralized sumps. Extensive use of water soluble cutting oils has also led to focus on efficient monitoring and maintenance of metal cutting fluids. It is easier to develop a good product than to make it consistently perform over a long duration. Well Begun Is Half Done - Sump charging We start with correct product selection and move on to thorough sump cleaning by recommended cleaning chemicals and rinsing the system which not only disinfect the system but also help flush out the sticky residues from the system. Water parameters like total hardness, chloride hardness, conductivity and pH are to be checked before sump charging and thereafter on a weekly basis. Top-Up & Monitoring Concentration of oil can be checked daily by refractometer and by titration for centralized tanks on a weekly basis. Correct concentration ensures high part quality, optimum tool performance and emulsion stability. pH of cutting fluid emulsions must be between 8.5 to 9.5 to ensure optimum corrosion protection and bio-stability of cutting oils. pH should be checked at least twice a week by calibrated digital meter or precise pH paper strips. Top-ups should be done by adding a measured quantity of pre-mix emulsions to the tank which can be made manually or by jet mixers. Crisis Management Unfavourable conditions like pH drop, bacterial contamination or sudden WIP corrosion issue need to be tackled quickly to ensure smooth operations. Tank side additives can help to counter such issues but they must be used with caution. Like medicines, they too have side effects if used in an incorrect dosage or method. Tramp Oil Menace Tramp oil (Leaked hydraulic oil, slideway oil etc.) floats over the emulsion, cutting off the contact with air which can lead to microbial contamination of the fluid. Tramp oil content must be kept lower than 0.5% of emulsion volume which can be done by using skimmers. Centralized tanks can also be connected to online centrifuge filtration systems. Importance Of Chip Removal Metal chip/swarf accumulation in the tank weakens emulsion and initiates bacterial infection in soluble cutting oils. They can be removed by an efficient filtration system as per the material being machined and the application. Chips can be removed by vacuum suction devices to maintain sump health. X-COOL Series: Advanced Water Soluble Metal Cutting Oils for High Performance The X-COOL series features premium water-soluble oils formulated with superior additive technology to ensure effective pH control and concentration stability. Our technical team implements efficient coolant management practices, resulting in high part quality, reduced oil consumption, and extended sump life. Conclusion Effective management of water-soluble metal cutting fluids is vital for optimizing machining processes. Proper maintenance and monitoring ensure superior quality and efficiency in manufacturing operations.

October 2024

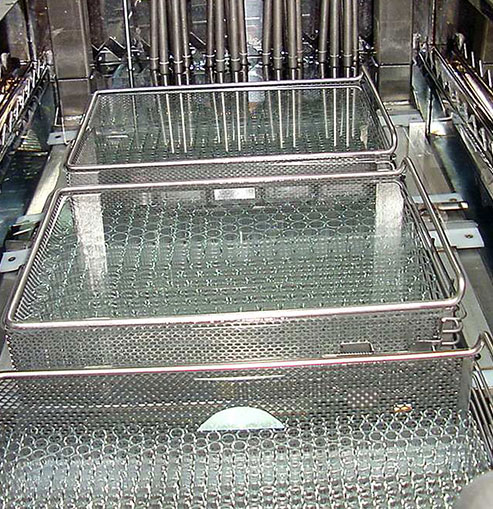

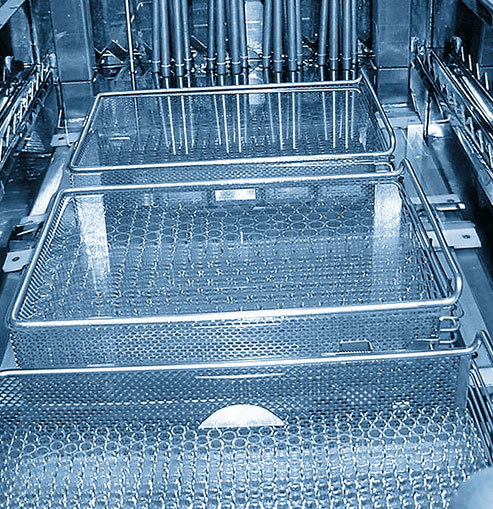

Industrial Ultrasonic Cleaners: Revolutionizing Cleaning Processes

Industrial Ultrasonic Cleaners: Revolutionizing Cleaning Processes Industrial Ultrasonic Cleaners have transformed how components and equipment are cleaned by developing necessary tools in various manufacturing and processing industries. These advanced cleaning systems are best at removing contaminants and debris from complex surfaces. This is carried out efficiently and with supreme precision by utilizing ultrasonic waves. This technology is capable of providing thorough cleaning in a non-destructive manner making it highly accepted in a large market. Industrial ultrasonic cleaners run on the basic principle of high-frequency sound wave generation that is above the range of human hearing. This follows a process known as cavitation where microscopic bubbles are formed due to the waves generated. These bubbles are utilized due to their popping ability that generates shockwaves strong enough to dislodge dirt, grease, and other contaminants from surfaces. With this method, many unreachable areas difficult to reach with traditional methods, may be cleaned thoroughly. Application of Industrial Ultrasonic Cleaners The utilization of industrial ultrasonic cleaners is spread across a mass of industries in the form of varying applications. These are known to play a crucial role in maintaining operational efficiency. 1. Manufacturing sector These cleaners are commonly used for cleaning components and degreasing equipment such as precision parts, gears, and other metal parts. 2. Electronics industry This ultrasonic cleaner industrial use has benefits to ensure that delicate circuit boards and microelectronics are cleaned thoroughly before use without causing any damage. 3. Automotive industry These are developed to clean various automotive parts. These parts span from carburettors and fuel injectors to engine components. With the automotive ultrasonic cleaner technology provided, removing contaminants like carbon deposits and oil residues has become more efficient with the help of a thorough and efficient cleaning solution. 4. Medical field These ultrasonic cleansers may be utilized for sterilizing and cleaning medical instruments and equipment. The unmatched precision and efficiency of ultrasonic cleaning make it an ideal choice for ensuring the safety and cleanliness of medical tools used in surgeries and other medical procedures. Importance of Industrial Ultrasonic Cleaners Industrial Ultrasonic Cleaners deliver high-quality cleaning results with precision and consistency. These are capable of minimizing manual labour and ensuring the least environmental impact. Traditionally, a lot of cleaning solutions utilized were highly toxic, filled with harsh chemicals, and used abrasive techniques often damaging delicate components and impacting the environment and human life. This modern version of cleaners is specialized and capable of reducing substantial dependency on chemicals by offering a more environmentally viable solution with ultrasonic cleaning chemicals. These cleaners are more efficient than the traditional versions contributing to time saving and cost balancing. This is why industries are streamlining their cleaning processes to enhance overall productivity. Due to the ultrasonic quality of cleaners, there is a no-contact policy inculcated. This ensures that delicate and complex components remain unmarried during the cleaning process and are exempted from the mechanical stress of traditional cleaners. This is beneficial to industries where precision and integrity of parts are required to be at the optimal level in the case of the aerospace and electronics arena. Advantages of Industrial Ultrasonic Cleaning There are numerous advantages of ultrasonic cleaners. This is why it is a preferred choice for various industries seeking efficient and reliable cleaning solutions. 1. The most important benefit it has relates to finding the most hard-to-reach areas to clean which was not possible initially using the traditional methods. The ultrasonic waves generate microscopic bubbles that penetrate the intricate areas such as crevices, blind holes, and other complex geometries to pop and shock the dirt into popping out. This ensures a thorough cleaning process. 2. Another important advantage is that the cleaning process through ultrasonic eliminated manual labor. This is due to new automatic methodologies that not only improves overall efficiency but also reduces the inevitable risk of human error. This ensures a consistent and reliable cleaning outcome using top-grade technology. 3. Furthermore, due to the no-contact policy of ultrasonic cleaning, it is essential to preserve the delicacy of surfaces. Traditional abrasive methods were damage prone but ultrasonic cleaning does not cause wear or damage to surfaces. This is the best solution to extend the lifespan of equipment and reduce the frequency of repairs and replacements. Choosing the Right Ultrasonic Cleaner Selecting the most appropriate industrial ultrasonic cleaner , there are numerous factors to consider to ensure maximum benefits and optimal performance is enabled. 1. Frequency and Power Based on the type of cleaning task, the power and frequency levels differ. Higher frequency is better utilized by the delicate components while lower frequency is best utilized for heavy-duty cleaning. To ensure that the right choice is made in terms of frequency and power levels, it is necessary to understand the cleaning requirements. 2. Tank Size and Capacity The size of the components to be cleaned must be proportionate to the size of the cleaner’s tank. This is because the components must be able to fit comfortably within the tank to ensure uniformity in cleaning. This is only possible when the volume and dimensions of the items and tank are studied thoroughly. 3. Material Compatibility If the cleaners do not have the right amount of compatibility with the items to be cleaned, the process of cleaning might become faulty or damage the surface. This can be done by ensuring that the items and surfaces are studied thoroughly. If there are sensitivities to certain cleaning agents, it must be taken into consideration. 4. Automation and Control Features The cleaning process may have the best overall efficiency only when the reactive advanced features contribute wholeheartedly. These features include programmable cleaning cycles, temperature control, and automation capabilities. A model with the best user-friendly controls and customization settings is capable of enhancing the flexibility and usability of the ultrasonic cleaner. 5. Maintenance and Serviceability A system is reliable for a longer time if it is easy to maintain and service. It is important to ensure that tank drainage is easier, routine maintenance is easily accessible, and the replacement parts are promptly available. Zavenir Daubert’s X-CLEAN Advance Aqueous Cleaners for Effective Ultrasonic Cleaning: In the range of Industrial Ultrasonic Cleaners, Zavenir Daubert has emerged as a frontrunner with its X-CLEAN Advance Aqueous Cleaners. These cutting-edge cleaners integrate the latest surfactant technology to elevate ultrasonic cleaning to new heights of effectiveness and efficiency. Zavenir Daubert’s X-CLEAN series stands out for its environmentally friendly composition. The cleaners are free from hazardous substances and toxic chemicals, aligning with the industry's growing emphasis on sustainable and eco-friendly practices. This contributes to a safer working environment and positions X-CLEAN as a responsible choice in the landscape of industrial cleaning solutions.

February 2024

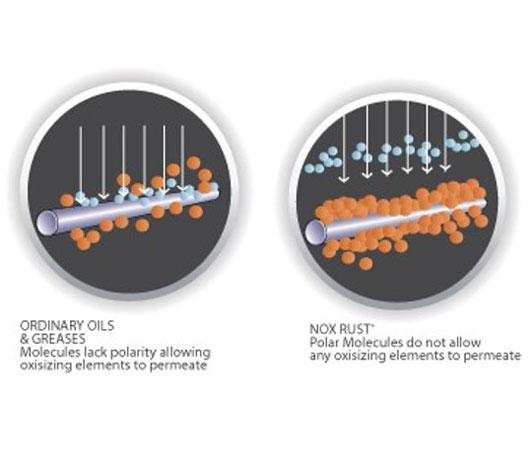

Dry to Touch Rust Preventive Oils Extend the Lifespan of Metal Components

Dry to Touch Oils Extend the Lifespan of Metal Components Metal objects are all around us, from tools to machines, and from automobiles to aeroplanes. But metals can face problems of rust, from its inception to its usage. Rust can make them weak and need to be fixed. But there's a solution called “Rust Preventive Oils." They form a temporary corrosion preventive barrier between a corrosive environment and metal. One of the important specifications that can solve the problem is Dry to touch rust preventive oils. What is Dry to Touch Oil? Metal components are at risk of corrosion and rust, which can significantly reduce their lifespan and compromise their functionality. These oils have emerged as a true leader in solving the crisis and taking up this challenge. Traditional rust preventive oils leave a wet or oily residue upon application while dry to touch oil create a protective barrier devoid of any greasy film. When you combine corrosion inhibitors and solvents, a typical solution achieved is the dry to touch rust preventive oils. These oils penetrate deep into the pores of metal surfaces, erecting a protective layer that shields against external elements such as moisture, oxygen, and other corrosive elements. These oils are innovative through their robust corrosion protection capability ensuring a dry, non-tacky finish, making them ideal for various applications across industries. How Dry to Touch Oils Extend the Lifespan of Metal Components? The metal components achieve longevity through the application of dry to touch rust preventive oils. As the name suggests, there is a feeling of dryness after application that ensures no dust and debris stick to the metal surface, thereby reducing the chances of abrasive wear. The resultant protective barrier formed is well-developed in the face of many environmental elements, preventing moisture from meeting the metal. This prevents corrosion as moisture is the prime catalyst. These oils play a pivotal role in preventing the degradation of the structure of the metal components when inhibiting corrosion. This, in the end, extends the lifespan of the metal while ensuring that the components maintain their integrity and functionality over time. What are the benefits of Dry to Touch Oils? Dry to touch oil offer numerous benefits that adds to the overall preservation and performance of metal components. 1. Their non-greasy finish makes them user-friendly, eliminating the need for additional cleaning after application. 2. This not only saves time but also reduces the consumption due to lower carryover losses. 3. Additionally, these oils provide excellent coverage and penetration, reaching even the most intricate parts of complex metal structures. 4. Their versatility allows for application on a wide range of surfaces, including ferrous and non-ferrous metals. Zavenir Daubert’s Nox-Rust® Dry to Touch Oil and its Thin Film Technology. Zavenir Daubert's Nox-Rust® Dry to Touch Oil works as a prominent corrosion protector. A uniform and seamless protective layer on metal surfaces may be realized through this thin film technology. This film adds to the aesthetic appeal via a nearly invisible coating. This is best for maximizing the efficiency of the rust preventive properties. The Nox-Rust® is an impressive combination of corrosion inhibitors’ formulation with long-term protection against rust and corrosion. Its dry feel finish is the best for industries where cleanliness and precision are paramount, including aerospace, automotive, steel, and electronics. . Our revolutionary methodology for the protection of the metal components utilized dry to touch rust preventive oils offering a superior solution to extends their lifespan and enhances their overall performance. Zavenir Daubert's Nox-Rust® Dry to Touch Oil stands as a testament to the continuous innovation in the field, providing industries with a reliable and efficient solution for their corrosion protection needs.

January 2024

Water Based Cleaner: Introduction, Advantages and Applications

Water Based Cleaner: Introduction, Advantages and Applications Water-based cleaners are modernizing the way industries accomplish cleaning tasks. In this comprehensive guide, we will get familiar with the cleaners that exist in industrial settings. We will be exploring their introduction, the pros and cons compared to other cleaner types and their purpose in industrial settings. There are some aspects to think over when picking the right cleaner which helps to know the best practices for their use. Here we have discussed about Zavenir’s X-Clean™ Cleaners, which comprise their incomparable features and benefits. Introduction to Water-Based Cleaners As the name implies, water is the key solvent in water-based cleaners. To boost the cleaner's cleaning efficiency a mixture of emulsifiers, surfactants, and additives are used. These are biodegradable, non-toxic, and environmentally friendly cleaners and thus have the least impact on the environment. Due to their superior efficiency they are becoming reasonably popular in industrial settings. Advantages and Disadvantages of Water-Based Cleaners Compared to Other Types of Cleaners Advantages : 1. Environmentally Friendly : They emit low volatile organic compound (VOC) which makes less impact on the environment and air quality. 2. Safety : The workplace and the workers can stay safe as these cleaners are non-toxic and non-flammable. 3. Versatility : These cleaners are appropriate for metals, plastics and ceramics surfaces. 4. Cost-Effective : They are a lot more cost-effective in comparison to other solvent-based substitutes. 5. Low Odor : These cleaners exude least or no stench; this further enhances comfort in workplace. Disadvantages : 1. Drying Time : Compared to solvent-based cleaners they may have longer drying times. 2. Rust Risk : If not managed properly surplus moisture can result in rust on metal surfaces. 3. Surface Compatibility : Several materials are sensitive to water, thus the applications of these cleaners is somehow limited. 3 Applications of Cleaners in Industrial Settings 1. Precision Cleaning : To get rid of contaminants from precision parts, tools, and machinery the cleaners are exceptionally useful. 2. Degreasing : They do extremely well in degreasing applications, eradicating grease and oil from surfaces. 3. Surface Preparation : Prior to bonding, coating, or painting, these cleaners are perfect for preparing the surfaces. 4. Maintenance Cleaning : For routine cleaning of industrial equipment and facilities they are always preferred. 5 Main Factors to Consider When Choosing the Right Water-Based Cleaner : 1. Contaminant Type : What kind of contaminants (oil, grease, dirt,) you want to remove must be taken into consideration. 2. Surface Material : Compatible materials like ceramics, plastics, metals, only should be cleaned with this cleaner. 3. Environmental Impact : The cleaner must be scrutinized for qualities like biodegradability, VOC content and environmental impact. 4.Regulatory Compliance : The right kind of cleaner always complies with the industry and regulatory principles. 5. Application Method : How it is applied, either spray or immersion or ultrasonic and the equipment’s compatibility must also be taken into consideration. Best Practices for Using Cleaners in Your Operations 1. Proper Dilution : The recommendations of the manufacturer must be followed to achieve the most advantageous cleaning performance. They always suggest the perfect dilution ratios. 2. Adequate Rinsing : Surfaces must be rinsed comprehensively, after cleaning, to get rid of residues. 3. Temperature Control : To attain a steady outcome, the cleaning solution‘s temperature must be controlled and watched closely. 4. Proper Ventilation : Make sure there is sufficient ventilation when cleaners are used. This helps in drying of surfaces and controls humidity. 5. Safety Precautions : Training is to be provided on cleaners’ safe use and handling, along with protective gear. Read More : Metal Surface Cleaners for Automotive Industry Zavenir’s X-Clean™ Cleaners Features and Benefits 1. Exceptional Cleaning : Zavenir’s X-Clean™ Cleaners proposes exceptional cleaning performance, taking out tough pollutants resourcefully. 2. Environmental Responsibility : These Cleaners are biodegradable, eco-friendly, and has VOC emissions of low impact. 3. Versatility : The X-Clean™ Cleaners are resourceful and appropriate for different industrial purposes. 4. Surface Compatibility : They are harmless for use on an extensive variety of materials, like metals, plastics, and ceramics. 5. Cost-Efficiency : X-Clean™ Water-Based Cleaners are cost-effective, endowing with exceptional worth for industrial cleaning needs. Due to their eco-friendly character, safety advantages, and versatility, these cleaners are gaining popularity in industrial settings. They can be very much effective in cleaning, degreasing, and surface preparation tasks when used properly and with the right considerations. Our Water-Based Cleaners symbolizes a leading example of advanced cleaning solutions. It also offers excellent features and advantages in industrial applications. For harnessing the full potential of cleaners in your operations, it is essential to select and use it correctly. Adhering to the best practices is also important.

November 2023

Metal Surface Cleaners for Automotive Industry

Metal Surface Cleaners for Automotive Industry Automotive components must meet high performance standards and ensure safety. To ensure the quality of these components, the use of cleaners is crucial. Therefore, it is of utmost importance to choose the appropriate automotive component cleaner. Several best practices can be applied to achieve optimal results. Metal surface cleaners are integral to manufacturing operations and play a pivotal role in improving component quality. Various types of cleaners with diverse properties are available. This comprehensive guide will help us to understand the variety of aspects related to automotive industry’s metal surface cleaners. Discussed here are the two products namely Zavenir - the X-Clean™ Aqueous Cleaner and the Dewatering Fluid Cum Solvent Cleaner. Let’s take a closer look at the attributes and advantages of these specific products. The Importance of Clean Metal Surfaces in Manufacturing Operations In the automotive industry, it is extremely crucial to keep the metal surfaces clean. This is influential in ensuring the quality, safety, and performance of the product. Equipments can break down and structural integrity can be jeopardized when metal surfaces have pollutants. To lessen maintenance expenses daily cleaning is an utmost necessity. The lifespan of machinery gets extended besides giving surety of high-quality automotive components. The overall competence and dependability of manufacturing operations is enhanced with clean metal surfaces. How Metal Surface Cleaners Can Improve Quality of Components The quality of automotive components gets enhanced with rigid tolerances and accurate machining. This happens when metal surfaces are cleanly maintained. To develop durability of component and decrease the threat of corrosion it is necessary to get rid of contaminants. Thus, optimal coating adhesion can be ensured. For the customer to be satisfied, only superior component quality can help. It is also helpful to have an enhanced overall automobile. Different Types of Metal Surface Cleaners and Their Properties There are different kinds of metal surface cleaners. It includes various eco-friendly alternatives, alkaline solutions and solvents. These cleaners have distinctive properties. To comply with the strict industry standards eco-friendly cleaners are used. They are biodegradable and environmentally responsible. For effective heavy-duty degreasing Solvent-based cleaners are used, whereas for removing oil and grease alkaline solutions are perfect. Choosing the Right Cleaner for Automotive Components To select the suitable cleaner, environmental impact, contamination levels and component material are the factors to be considered. For resourceful and successful cleaning, the most appropriate cleaner should be selected after consultation with experts and compatibility tests. Best Practices for Implementing Metal Surface Cleaners To implement metal surface cleaners in the facility in a productive way, it is necessary to have properly trained staff. During the process of cleaning, the use of protective gear as a safety measure must be followed strictly. To perform an operation in a safe and efficient approach, the cleaning equipments must go through regular maintenance. The recommendations of manufacturer also need to be obeyed. Zavenir’s X-Clean™ Aqueous Cleaner Features and Benefits Zavenir's X-Clean™ is a metal surface cleaner specifically devised for automotive applications. It provides excellent degreasing properties, efficiently taking out oils, grease, and contaminants from metal surfaces. X-Clean™ offers advanced rust prevention potential, ensuring long-lasting safety for automotive components. Environmentally friendly and biodegradable, it holds up with industry standards for sustainability. X-Clean™ boost cleaning efficiency, enhances component quality, and improves manufacturing productivity. Zavenir’s Dewatering Fluid Cum Solvent Cleaner Features and Benefits Zavenir’s Dewatering Fluid Cum Solvent Cleaner is distinctively created for the automotive industry. It is efficient in degreasing and corrosion protection and is perfect for different automotive manufacturing processes. The solvent cleaner is resourceful and well-suited for a variety of metals and types of surfaces. It contributes to a cleaner and more competent production atmosphere, endorsing high-quality automotive components. Zavenir’s Dewatering Fluid Cum Solvent Cleaner is a trustworthy solution for preserving the integrity of metal surfaces in automotive manufacturing.

October 2023

Industrial Degreaser for Manufacturing Processes

Industrial Degreaser for Manufacturing Processes In the dynamic landscape of manufacturing, precision and cleanliness are paramount. Industrial degreasers are the unsung heroes that ensure machinery and components function flawlessly. This comprehensive guide will explore the significance of cleanliness and degreasing in manufacturing operations, how industrial degreasers enhance component quality, the various types of degreasers and their properties, selecting the right degreaser for specific applications, best practices for implementation, and a closer look at Zavenir’s X-Clean™ Aqueous Industrial Degreaser, including its standout features and benefits. Promoting Cleanliness and Degreasing in Manufacturing Operations Cleanliness is not just a preference but a prerequisite in manufacturing to ensure product quality, safety, and optimal performance. Contaminants such as grease, oil, and dirt on surfaces can lead to defects, compromised structural integrity, and equipment malfunction. Regular degreasing reduces maintenance costs, extends machinery lifespan, and ensures the production of high-quality components. Clean surfaces are vital for the overall efficiency and reliability of manufacturing processes. How Industrial Degreasers Can Enhancing the Quality of Components Industrial degreasers efficiently remove grease, oil, and contaminants from surfaces, enhancing the quality of components. The removal of contaminants ensures optimal adhesion for coatings, reduces the risk of corrosion, and improves component durability. Improved component quality leads to a superior final product, increased customer satisfaction, and reduced warranty claims. Types of Industrial Degreasers and Their Properties Industrial degreasers come in various types, including solvent-based, water-based, and bio-based, each with distinct properties. 1. Solvent-based degreasers: Solvent-based degreasers excel in heavy-duty degreasing, effectively breaking down tough contaminants. 2. Water-based degreasers: Water-based degreasers are environmentally friendly and provide an eco-conscious option for cleaning. 3. Bio-based degreasers: Bio-based degreasers are biodegradable, aligning with sustainability standards, and are safe for both personnel and the environment. Selecting the Appropriate Industrial Degreaser for Your Unique Application Selecting the appropriate degreaser involves considering factors such as the type of contamination, surface material, and environmental impact. Compatibility tests and consultation with experts ensure the selection of the most suitable degreaser for efficient and effective cleaning. Zavenir’s X-Clean™ Aqueous Industrial Degreaser offers a versatile solution suitable for various applications, simplifying the selection process. Read Also: Clean your components at Low Temperature: An Overview of Low Temperature Cleaners Optimizing Industrial Degreaser Usage in Your Facility: Best Practices Proper training of personnel is essential for the successful implementation of industrial degreasers. Safety measures, including the use of protective gear, must be strictly followed during the degreasing process to protect personnel and the workplace. Regular maintenance of degreasing equipment and adherence to manufacturer recommendations are crucial for safe and efficient operations. Zavenir’s X-Clean™ Aqueous Industrial Degreaser enhances cleaning efficiency, improves component quality, and contributes to a cleaner and more efficient production environment. Zavenir’s X-Clean™ Aqueous Industrial Degreaser Features and Benefits: Zavenir's X-Clean™ Aqueous Industrial Degreaser is a high-performance solution designed for industrial applications. It boasts exceptional degreasing properties, effectively removing oils, grease, and contaminants from surfaces. The degreaser offers superior rust prevention capabilities, ensuring long-lasting protection for components. Environmentally friendly and biodegradable, it aligns with industry standards for sustainability and safety. X-Clean™ Aqueous Industrial Degreaser enhances cleaning efficiency, improves component quality, and promotes a more efficient production environment. Its versatile formulation is compatible with a wide range of materials, making it suitable for various industrial applications. The right industrial degreaser is an indispensable tool in manufacturing, ensuring the production of high-quality components and overall efficiency. Cleanliness and degreasing are not optional but imperative for product quality, safety, and longevity. Zavenir's X-Clean™ Aqueous Industrial Degreaser represents an advanced solution designed to meet the specific needs of industrial applications, offering exceptional features and benefits that contribute to the success of the industry. Proper selection, implementation, and maintenance of industrial degreasers are vital steps toward achieving the desired cleanliness and quality in manufacturing operations.

October 2023

Clean your components at Low Temperature: An Overview of Low Temperature Cleaners

Clean your components at Low Temperature: An Overview of Low Temperature Cleaners Introduction to Low Temperature Cleaners : Low temperature cleaners clean effectively in lower temperatures, ideal when high heat isn't feasible. They're efficient, eco-friendly, and cost-effective for industries needing top-notch cleaning without excessive energy use. Low-temperature cleaning agents are purpose-built cleaning solutions. They are engineered to efficiently cleanse surfaces and equipment using lower temperatures compared to conventional cleaners. These cleaning agents are specially crafted to maintain their effectiveness even in typical environmental conditions. They are appropriate for tasks where conducting high-temperature cleaning is neither possible nor pragmatic. Low-temperature cleaners present a cutting-edge answer for industries demanding thorough cleaning without the necessity for excessive heat. They deliver exceptional cleaning outcomes while simultaneously diminishing energy consumption and operational expenses. How Low Temperature Cleaners works and their Benefits : Low temperature cleaners operate by harnessing distinctive formulations that empower them to perform effectively at lower temperatures. They typically spanning from room temperature to modest heating. These cleaners leverage advanced surfactants and chemical agents to disintegrate dirt, grease, and impurities, facilitating their removal from surfaces. The advantages of low temperature cleaners comprise energy conservation, diminished carbon emissions, and the capability to clean heat-sensitive materials and equipment without jeopardizing their structural integrity. Applications of Low Temperature Cleaners in Manufacturing Operations : 1. Food and Beverage Industry : Low temperature cleaners ensures adherence to hygiene standards. They are used for cleaning food processing equipment and facilities. Thus, the risk of contaminating perishable goods is prevented. 2. Electronics Manufacturing : Sensitive electronic components are cleaned with this cleaner to get rid of flux residues and impurities. Low temperature cleaner also shields such components to high temperature exposures. It preserves and protects the electronic devices from any potential damage. 3. Automotive and Aerospace Industries : To ensure optimum performance of delicate engine components and aerospace parts, the Low temperature cleaners are used. It also helps to avoid any thermal stress. 4. Medical Device Manufacturing : Medical equipment and instruments that demand a gentle yet efficient approach are cleaned using this cleaner. It maintains the sterility of equipments and instruments and guarantees the safety of patients. 5. Pharmaceutical Industry : In cleaning pharmaceutical processing equipment and facilities a crucial role is played by low temperature cleaners. With compliance to regulations, it ensures product safety, particularly for heat-sensitive drugs. 6. Textile Industry : To preserve delicate fabrics and materials from damage or shrinkage, low temperature cleaners are applied throughout the cleaning process. 7. Painting and Coating Operations : These cleaners can efficiently clean surfaces prior to painting or coating, making sure of suitable adhesion and smooth finishing. 8. Precision Manufacturing : Low temperature cleaners are employed in accurate cleaning procedures for crucial components, optics, and semiconductor parts. 9. Printing Industry : Ink residues and contaminants are successfully removed from printing equipment and machinery by low temperature cleaners. It helps in maintaining the print quality. Choosing the Right Low Temperature Cleaner for Specific Application : 1. Cleaning Task : To choose the most appropriate low temperature cleaner, the specific cleaning requirements and form of contaminants is to be recognized. A special cleaner is devised for a particular cleaning task. 2. Surface Compatibility : To prevent any damage or discoloration on the material or surface being cleaned make sure that the cleaner is harmless and capable. Before using it comprehensively, carry out compatibility tests on a little area. 3. Environmental Impact : There is always a preference for biodegradable and environmentally friendly cleaners. So, consider using eco-friendly options. Thus, it aligns with sustainability goals and environmental regulations are also fulfilled. 4. Health and Safety : Some cleaners may pose health risks due to chemicals or unsafe fumes. Therefore, to protect workers' health opt for cleaners with less toxicity and correct safety instructions. 5. Cleaning Efficiency : To estimate a cleaner’s performance carry out trials and understand the product specifications. It is also important to evaluate the cleaner's effectiveness at low temperatures. The cleaner must have the capacity to break down and get rid of contaminants successfully. 6. Residue-Free Cleaning : Select cleaners that leave behind negligible to no residue. Residue-free cleaning may be crucial in certain applications. This is to keep away from interference with ensuing processes. 7. Cost Considerations : To find out the overall cost, take into consideration factors like cleaning frequency, cleaning performance and dilution ratios. For any particular application, calculate the cost-effectiveness of the cleaner. Read Also : The Ultimate Guide to Industrial Cleaning Solutions Best Practices for Implementing Low Temperature Cleaners in Manufacturing Facility : 1. Testing and Validation : Prior to complete implementation; perform compatibility and efficiency tests. This will ensure that the performance of the cleaner is as expected at low temperatures. 2. Equipment and Storage : To maintain the effectiveness of cleaner, the storage methods and cleaning equipment must be used appropriately. The cleaners should be stored as per the guidelines of manufacturer to avoid degradation. 3. Safety Protocols : Using personal protective equipment and implementing safety protocols is necessary while handling the low temperature cleaners. Gloves and eye protection gears must be provided to employees for proper safety. 4. Application Methods: For most favourable application, the manufacturer’s recommendations need to be followed. To make sure smooth distribution of the cleaner, foaming, immersion or spraying are fitting application methods. 5. Monitoring and Quality Control: To make certain consistent cleaning results, apply quality control measures. Monitor the cleaning process regularly. For process validation, cleaning parameters and outcomes are also to be recorded. 6. Waste Disposal: For handling as well as disposing of cleaning agents, local guidelines are to be followed. Cleaning waste and residues needs to be disposed properly as per environmental regulations. 7. Employee Training : To avoid slip-ups and mishaps by employees, proper training is to be provided. Employees must use and handle low temperature cleaners in correct manner. They need to know well the potential hazards and safety protocols also. 8. Supplier Collaboration : Stay well-connected with cleaning solution suppliers to get updates regarding new products. For effective implementation of best practices and specific application challenges do consult with the suppliers. 9. Continuous Improvement : To spot out areas for improvement and enhance efficiency, analyze and evaluate the cleaning process constantly. Cleaning performance can also be enhanced by integrating feedback from employees and suppliers. Zavenir’s X-Clean™ Low Temperature Cleaner features and benefits: Zavenir's X-Clean™ Low Temperature Cleaner is a revolutionary cleaning solution that comes with a variety of noteworthy characteristics and benefits, as well as energy-saving capabilities, making it an ideal preference for industrial and commercial cleaning applications. The main aspect of X-Clean™ is its specific formulation for low-temperature cleaning. This feature makes it perfect for susceptible materials and heat-sensitive equipment, decreasing the threat of damage and lengthening the lifetime of cleaned items. One of the prime advantages of X-Clean™ is its dominant degreasing characteristics. Its alkaline composition permits it to successfully break down and get rid of tough grease, stains, and contaminants, providing outstanding cleaning performance while removing the necessity for callous chemicals and high-temperature washes. Moreover, X-Clean™ is extremely handy and well-suited with a wide variety of materials, such as metals, plastics, ceramics, and glass. This flexibility ensures its appropriateness for different cleaning tasks, making simpler the cleaning procedure in varied industrial settings. Another important benefit of X-Clean™ is its energy-saving trait. The low-temperature cleaning potential not only trims down the energy consumption through the cleaning method but also adds to lower overall operational expenses. Additionally, the cleaner's quick action and rapid rinsing properties extensively lessen cleaning time, increasing productivity, and further having a say in saving energy.

September 2023

The Ultimate Guide to Industrial Cleaning Solutions

The Ultimate Guide to Industrial Cleaners Introduction to Industrial Cleaners In the manufacturing and industrial settings, the use of specific cleaning agents known as industrial cleaning solutions is dominant. These solutions are thoroughly designed to deal with some difficult tasks. They eliminate stubborn residues, contaminants, grease, and grime that accumulate on components, machinery, equipment, surfaces, and workspaces. They play an important role in cleanliness. Besides, these cleaning solutions are influential in maintaining hygiene standards. They also optimize operational efficiency within manufacturing facilities. This commitment to cleanliness guarantees seamless production procedures and steadfast adherence to strict safety regulations. Industrial cleaning solutions are devised to confront the distinctive cleaning challenges prevailing in industrial environments. They manifest in diverse forms, encompassing solvents, degreasers, detergents, acids, and environmentally friendly, biodegradable alternatives. Armed with formidable cleaning capabilities, these solutions have emerged as indispensable instruments for the attainment of immaculate and productive industrial workspaces. Types of Industrial Cleaners and their applications 1. Solvent Cleaners: Applied for eliminating oil, grease, and adhesives from metal surfaces, machinery, and parts in manufacturing, automotive, and aerospace industries. 2. Degreasers: Designed especially to liquefy and eradicate grease, oils, and hydrocarbon-based impurities from different surfaces, perfect for industrial equipment, engines, and maintenance. 3. Alkaline Cleaners: Appropriate for heavy-duty cleaning tasks, like removing immovable stains, dirt and residues from industrial equipment, floors, and processing plants. 4. Acid Cleaners: Applied for descaling, getting rid of mineral deposits, and deal with rust and oxide layers on metal surfaces in manufacturing and metal processing industries. 5. Biodegradable Cleaners: Eco-friendly substitutes, appropriate for cleaning susceptible equipment and surfaces without harming the environment, generally used in eco-conscious industries and for cleaning food processing equipment. 6. Disinfectants and Sanitizers: Designed to eradicate bacteria, viruses, and pathogens, important for upholding hygienic conditions in pharmaceutical, healthcare, and food processing industries. 7. Precision Cleaners: intended to use for particular applications such as electronics cleaning, ultrasonic cleaning, and critical parts cleaning in aerospace, semiconductor, and medical device manufacturing. Read Also : The Benefits of Using Soluble Cutting Oil in Metalworking Operations Advantages of using Industrial Cleaners in Manufacturing Operations 1. Superior Equipment Performance: Using Industrial Cleaning Chemicals daily prevents accumulation of contaminants. It leads to improved performance and durability of machinery and equipment. Clean equipment functions more capably and experiences lesser breakdowns, decreasing downtime and maintenance costs. 2. Security and Fulfilment: Clean environments lessen workplace mishaps, ensure compliance with safety standards, and build a healthier work environment for employees. Machinery and workspaces cleaned appropriately curtail slip and fall risks and possible exposure to injurious substances. 3. Quality Control: Clean surfaces and equipment avert cross-contamination and make certain product quality in manufacturing procedures. Cleaner equipment and workspaces bring about products of higher-quality and lessen the threat of defects. 4. Improved Effectiveness: Taking out residues and dirt develops energy efficiency, decrease friction, and enhance production throughput. Smoothly running machinery needs less power and resources, ensuing in cost savings. 5. Preventive Maintenance: Regular cleaning of equipment prevents corrosion, degradation, costly repairs, and extends its longevity. Preventive maintenance is more reasonable than reactive repairs and replacements. 6. Environmental Responsibility: Eco-friendly Industrial Cleaning Chemicals solutions support sustainable practices and diminish the environmental impacts of manufacturing processes. Choosing biodegradable and environmentally friendly cleaners aligns with corporate social responsibility programmes. Factors to be considered for choosing the Right Industrial Cleaning Solution 1. Cleaning Task: Recognize the exact cleaning tasks and kinds of contaminants to choose the most fitting cleaner. Different contaminants need different cleaning agents and process. 2. Surface Compatibility: Make sure that the cleaner is harmless and effectual on the material or surface being cleaned to check damage or discoloration. 3. Environmental Impact: Think about eco-friendly options to align with sustainability goals and abide by the environmental guidelines. Biodegradable and eco-friendly cleaners are favoured. 4. Health and Safety: Select products with low toxicity and suitable safety directions to safeguard workers' health. Don’t choose cleaners with unsafe vapours or chemicals that may cause health threats. 5. Concentration and Dilution: Choose for Industrial Cleaning Chemicals with the proper concentration or dilution ratios for profitable and proficient cleaning. Correct dilution makes certain the cleaner's efficiency without misuse. 6. Residue-Free Cleaning: Residue-free cleaning may be necessary in certain applications to evade meddling with consequent processes, like painting or welding. 7. Ease of Use: User-friendly products and application methods perks up cleaning effectiveness and cut human mistakes. Consider factors such as spray, dipping, ultrasonic or automatic cleaning systems for handiness. Best Practices for implementing the Industrial Cleaning Solutions in Manufacturing Operations 1. Train Employees: Provide comprehensive training to the employees for safe and professional use of industrial cleaning products, covering handling, storage, and application techniques. 2. Storage and Handling: Adhere to storage recommendations for cleaner longevity. Keep them in original containers in a cool, dry, and secure place, away from sunlight and extreme temperatures. 3. Adequate Ventilation: Guarantee that there is effective airflow in cleaning zones to lessen the hazard of inhaling fumes or aerosols. Use exhaust fans or carry out cleaning activities within spaces that have excellent natural ventilation. 4. Testing and Validation: Before using it extensively, do compatibility and efficacy tests. Validate a cleaner's performance on a small area or test piece ahead of applying it to the complete surface or equipment. 5. Safety Protocol Compliance: Ensure adherence to safety rules, including the use of personal protective gear like gloves, eye protection, and masks to avoid calamity when handling the cleaning agent. 6. Routine Maintenance: Plan and carry out regular cleaning and maintenance to prevent build-up and maintain consistent cleanliness. Tailor the cleaning schedule to equipment usage and manufacturing requirements. 7. Eco-Friendly Disposal: Follow the environmental rules when disposing of cleaning waste and remains. To prevent environmental damage, obey the local guidelines for harmless disposal of cleaning agents and wastewater. 8. Continuous Improvement: Calculate the cleaning process regularly to find out efficiency progress. Review at regular intervals and take counteractive measures to improve performance. 9. Collaborate with Suppliers: Team up with Industrial Cleaning Chemicals suppliers for product insights and best practices. Maintain open communication for expert guidance and stay updated on the latest industrial cleaning innovations. Zavenir’s X-Clean™ Alkaline Industrial Cleaner features and benefits X-Clean™ Alkaline Industrial Cleaner is an advanced and extremely useful Industrial Cleaning Chemicals solution intended to fulfil the challenging requirements of industrial settings. This dominant cleaner combines a distinctive mix of alkaline agents and specialized additives. X-Clean™ removes brilliantly tough grease, oil, manufacturing process fluids, grime, and stubborn stains from different surfaces like concrete, ceramics and metal. It is a perfect preference for heavy-duty industrial cleaning tasks because of its superior cleaning performance. It also saves time and labour costs. X-Clean™ is devised with eco-friendly components. It maintains high cleaning effectiveness and ensures minimal environmental impact. It is biodegradable and fulfils with all applicable environmental regulations, increasing sustainability plans for businesses. X-Clean™ don’t contain harsh solvents or toxic fumes therefore it is safe for workers, who are constantly exposed to it. X-Clean™ is versatile as it is appropriate for a range of industries. It is widely adapted in aerospace, automotive, defence, manufacturing, etc. It even has operational flexibility as it can be used for both manual and automated cleaning applications.

September 2023

The Benefits of Using Water Soluble Cutting Oil in Metalworking Operations

The Benefits of Using Water Soluble Cutting Oil in Metalworking Operations : In metalworking, the use of Soluble cutting oil is significantly beneficial. Besides improving surface finish, it prolongs tool life and decreases friction and heat while cutting. As the oil works as a coolant, it enhances machining precision and avoids distortion of the workpiece. To keep the cutting area clean this oil helps in the removal of chips. This is a valuable feature to minimize the downtime of machines. The Soluble cutting oil has properties of corrosion protection which lengthen the lifetime of equipments. This oil ensures a harmless working environment because it also possesses biocidal properties. Eventually, metalworking efficiency and productivity get enhanced when superior cutting speeds and feeds occur. What is Water Soluble Cutting Oil and How Does it Work ? A lubricant used in metalworking procedures is Water Soluble cutting oil. It is also referred to as cutting fluid or coolant. It contains additives, emulsifiers, and synthetic or mineral oil. To create a stable solution, the oil has to get mixed with water which is achieved by the emulsifiers. The oil shapes up into a thin film amid the workpiece and cutting tool when applied to the cutting area. During metalworking, to cut down heat, friction, and wear this film of oil works wonders. It improves cutting operations and extends tool life. The Soluble cutting oil prevents the workpieces from thermal damage. It is useful in dispersing heat from the cutting zone as it works like a coolant too. The oil is very handy in keeping clean the working zone. It increases the efficiency of machining with efficient chip removal quality. Advantages of Using Water Soluble Cutting Oil in Metalworking Processes : The application of oil during the metalworking course puts forward many advantages. To make tools last longer and achieve better cutting performance, the abrasion between the cutting tool and workpiece gets reduced. Working as a coolant, the workpiece gets protected from thermal damage and disperses heat from the cutting area. This is beneficial in getting the surface finish and dimensional precision. Prevents machine blockages and maintains a clean working location by making easy the removal of swarf and chips. Hence, machine downtime gets reduced. Extends the longevity of the machine and workpiece by providing protection against corrosion. Makes the working environment safe by warding off bacterial growth with biocidal properties. Generally, the oil use boosts metalworking effectiveness, output, and earnings. Different Types of Soluble Cutting Oils and Their Properties : For specific metalworking applications and materials, there are different varieties of soluble cutting oils available. Some cutting fluids are mineral oil-based and they offer excellent lubrication and are reasonable. However, they may have restricted biodegradability value. Another kind of cutting fluid which is a combination of synthetic additives and mineral oil is the semi-synthetic cutting oil. They have the properties of superior corrosion protection, lubrication and cooling. This cutting oil is more stable than mineral cutting oil. For high-speed machining and demanding applications, the fully synthetic cutting fluid gets used. It is chemically engineered oil that brings forth corrosion resistance properties, exceptional lubrication and proper cooling. The type of cutting oil that is gaining rapid popularity is vegetable-based cutting oil. It is derived from renewable sources and has eco-friendly qualities like low toxicity and biodegradability. The factors like machining requirements, workpiece material, environmental considerations and operator safety are the main factors that influence the selection of water soluble cutting oils. Factors to Consider When Choosing the Right Oil for Your Application : Choosing the correct soluble cutting oil is decisive for best possible metalworking performance. Think about the definite machining procedures and resources used in your procedure. Some oils are devised to do well in particular applications. Evaluate the environmental consequences and regulatory needs. A number of oils are more eco-friendly and fits well with different guidelines. Assess the lubrication and cooling properties obligatory. Fully synthetic oils go well for high-speed or heavy-duty operations, while semi-synthetic or mineral-based are beneficial for standard operations. Consider the oil's durability and constancy, and how compatible it is with your machine's filtration and recycling systems. Calculate the aspects of health and safety, like allergic reactions or probable skin irritation. Discuss with lubricant suppliers. To make sure the particular cutting oil fulfils all your criteria carry out tests. It must give out the best performance and worth for your metalworking application. Read Also : An Eco-Friendly Solution : Exploring Environmentally Friendly Cutting Oil Best Practices for Implementing Soluble Cutting Oil in Metalworking Operations : During metalworking operations, implementing oil can be a significant enhancement. To make certain that cutting oil produces the desired outcome or results, do follow these finest practices : To keep the stability and effectiveness of cutting oil, do confirm that the mix of the oil with water is accurate. Performance setbacks can get avoided by regular monitoring and maintaining fluid concentration. For lengthening the lifespan of the fluid, use enough filtration systems to get rid of contaminants. It is important to change or regenerate the cutting fluid daily so that it performs reasonably. Protecting operators from potential hazards, such as aerosols and mist produced during machining, is absolutely crucial. To keep employees safe, provide personal protective equipment and maintain good ventilation. Workers handling cutting fluid should receive proper training. They must know about storing the fluid and dispose of it safely. This would minimize wastage also. For the metalworking operations to run smoothly, equipment damage needs to be prevented. The fluid systems and machines require a routine maintenance schedule to be met. Zavenir Daubert has environmentally friendly, safe and high-performance water-soluble cutting oils X-COOL®, which cannot only increase the machining efficiency but also reduce the overall cost.

August 2023

Environmental Friendly Cutting Oil: An Eco-Friendly Solution