September 2023

September 2023The Ultimate Guide to Industrial Cleaners

Introduction to Industrial Cleaners

In the manufacturing and industrial settings, the use of specific cleaning agents known as industrial cleaning solutions is dominant. These solutions are thoroughly designed to deal with some difficult tasks. They eliminate stubborn residues, contaminants, grease, and grime that accumulate on components, machinery, equipment, surfaces, and workspaces. They play an important role in cleanliness. Besides, these cleaning solutions are influential in maintaining hygiene standards. They also optimize operational efficiency within manufacturing facilities. This commitment to cleanliness guarantees seamless production procedures and steadfast adherence to strict safety regulations.

Industrial cleaning solutions are devised to confront the distinctive cleaning challenges prevailing in industrial environments. They manifest in diverse forms, encompassing solvents, degreasers, detergents, acids, and environmentally friendly, biodegradable alternatives. Armed with formidable cleaning capabilities, these solutions have emerged as indispensable instruments for the attainment of immaculate and productive industrial workspaces.

Types of Industrial Cleaners and their applications

1. Solvent Cleaners: Applied for eliminating oil, grease, and adhesives from metal surfaces, machinery, and parts in manufacturing, automotive, and aerospace industries.

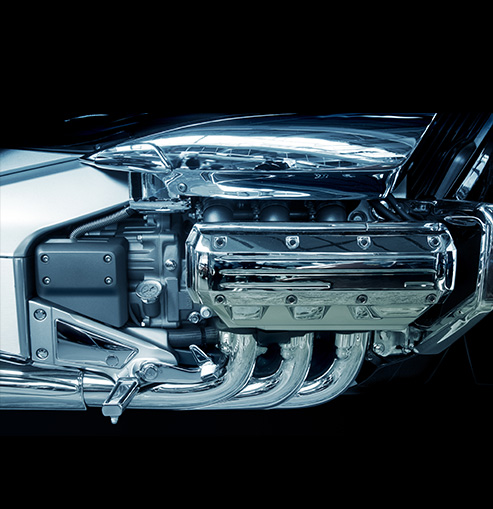

2. Degreasers: Designed especially to liquefy and eradicate grease, oils, and hydrocarbon-based impurities from different surfaces, perfect for industrial equipment, engines, and maintenance.

3. Alkaline Cleaners: Appropriate for heavy-duty cleaning tasks, like removing immovable stains, dirt and residues from industrial equipment, floors, and processing plants.

4. Acid Cleaners: Applied for descaling, getting rid of mineral deposits, and deal with rust and oxide layers on metal surfaces in manufacturing and metal processing industries.

5. Biodegradable Cleaners: Eco-friendly substitutes, appropriate for cleaning susceptible equipment and surfaces without harming the environment, generally used in eco-conscious industries and for cleaning food processing equipment.

6. Disinfectants and Sanitizers: Designed to eradicate bacteria, viruses, and pathogens, important for upholding hygienic conditions in pharmaceutical, healthcare, and food processing industries.

7. Precision Cleaners: intended to use for particular applications such as electronics cleaning, ultrasonic cleaning, and critical parts cleaning in aerospace, semiconductor, and medical device manufacturing.

Read Also : The Benefits of Using Soluble Cutting Oil in Metalworking Operations

Advantages of using Industrial Cleaners in Manufacturing Operations

1. Superior Equipment Performance: Using Industrial Cleaning Chemicals daily prevents accumulation of contaminants. It leads to improved performance and durability of machinery and equipment. Clean equipment functions more capably and experiences lesser breakdowns, decreasing downtime and maintenance costs.

2. Security and Fulfilment: Clean environments lessen workplace mishaps, ensure compliance with safety standards, and build a healthier work environment for employees. Machinery and workspaces cleaned appropriately curtail slip and fall risks and possible exposure to injurious substances.

3. Quality Control: Clean surfaces and equipment avert cross-contamination and make certain product quality in manufacturing procedures. Cleaner equipment and workspaces bring about products of higher-quality and lessen the threat of defects.

4. Improved Effectiveness: Taking out residues and dirt develops energy efficiency, decrease friction, and enhance production throughput. Smoothly running machinery needs less power and resources, ensuing in cost savings.

5. Preventive Maintenance: Regular cleaning of equipment prevents corrosion, degradation, costly repairs, and extends its longevity. Preventive maintenance is more reasonable than reactive repairs and replacements.

6. Environmental Responsibility: Eco-friendly Industrial Cleaning Chemicals solutions support sustainable practices and diminish the environmental impacts of manufacturing processes. Choosing biodegradable and environmentally friendly cleaners aligns with corporate social responsibility programmes.

Factors to be considered for choosing the Right Industrial Cleaning Solution

1. Cleaning Task: Recognize the exact cleaning tasks and kinds of contaminants to choose the most fitting cleaner. Different contaminants need different cleaning agents and process.

2. Surface Compatibility: Make sure that the cleaner is harmless and effectual on the material or surface being cleaned to check damage or discoloration.

3. Environmental Impact: Think about eco-friendly options to align with sustainability goals and abide by the environmental guidelines. Biodegradable and eco-friendly cleaners are favoured.

4. Health and Safety: Select products with low toxicity and suitable safety directions to safeguard workers' health. Don’t choose cleaners with unsafe vapours or chemicals that may cause health threats.

5. Concentration and Dilution: Choose for Industrial Cleaning Chemicals with the proper concentration or dilution ratios for profitable and proficient cleaning. Correct dilution makes certain the cleaner's efficiency without misuse.

6. Residue-Free Cleaning: Residue-free cleaning may be necessary in certain applications to evade meddling with consequent processes, like painting or welding.

7. Ease of Use: User-friendly products and application methods perks up cleaning effectiveness and cut human mistakes. Consider factors such as spray, dipping, ultrasonic or automatic cleaning systems for handiness.

Best Practices for implementing the Industrial Cleaning Solutions in Manufacturing Operations

1. Train Employees: Provide comprehensive training to the employees for safe and professional use of industrial cleaning products, covering handling, storage, and application techniques.

2. Storage and Handling: Adhere to storage recommendations for cleaner longevity. Keep them in original containers in a cool, dry, and secure place, away from sunlight and extreme temperatures.

3. Adequate Ventilation: Guarantee that there is effective airflow in cleaning zones to lessen the hazard of inhaling fumes or aerosols. Use exhaust fans or carry out cleaning activities within spaces that have excellent natural ventilation.

4. Testing and Validation: Before using it extensively, do compatibility and efficacy tests. Validate a cleaner's performance on a small area or test piece ahead of applying it to the complete surface or equipment.

5. Safety Protocol Compliance: Ensure adherence to safety rules, including the use of personal protective gear like gloves, eye protection, and masks to avoid calamity when handling the cleaning agent.

6. Routine Maintenance: Plan and carry out regular cleaning and maintenance to prevent build-up and maintain consistent cleanliness. Tailor the cleaning schedule to equipment usage and manufacturing requirements.

7. Eco-Friendly Disposal: Follow the environmental rules when disposing of cleaning waste and remains. To prevent environmental damage, obey the local guidelines for harmless disposal of cleaning agents and wastewater.

8. Continuous Improvement: Calculate the cleaning process regularly to find out efficiency progress. Review at regular intervals and take counteractive measures to improve performance.

9. Collaborate with Suppliers: Team up with Industrial Cleaning Chemicals suppliers for product insights and best practices. Maintain open communication for expert guidance and stay updated on the latest industrial cleaning innovations.

Zavenir’s X-Clean™ Alkaline Industrial Cleaner features and benefits

X-Clean™ Alkaline Industrial Cleaner is an advanced and extremely useful Industrial Cleaning Chemicals solution intended to fulfil the challenging requirements of industrial settings. This dominant cleaner combines a distinctive mix of alkaline agents and specialized additives.

X-Clean™ removes brilliantly tough grease, oil, manufacturing process fluids, grime, and stubborn stains from different surfaces like concrete, ceramics and metal. It is a perfect preference for heavy-duty industrial cleaning tasks because of its superior cleaning performance. It also saves time and labour costs.

X-Clean™ is devised with eco-friendly components. It maintains high cleaning effectiveness and ensures minimal environmental impact. It is biodegradable and fulfils with all applicable environmental regulations, increasing sustainability plans for businesses.

X-Clean™ don’t contain harsh solvents or toxic fumes therefore it is safe for workers, who are constantly exposed to it.

X-Clean™ is versatile as it is appropriate for a range of industries. It is widely adapted in aerospace, automotive, defence, manufacturing, etc. It even has operational flexibility as it can be used for both manual and automated cleaning applications.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)