July 2022

July 2022VCI: The Anti Corrosive Packaging

One of the best ways to prevent corrosion from occurring is through a refined packaging material that utilizes the properties of the anti-rust additives while ensuring high volatility of VCI molecules and settling on the metal surface. This way that packaging can ensure complete coverage and corrosion inhibition of metals. The packaging is termed Volatile Corrosion Inhibition (VCI) which is popularly known as the anti-corrosive packaging.

Utility and Applications of Anti Rust Packaging?

When you put stress on the terminology ‘anti-rust packaging’ you indeed highlight the basic feature of this product which is a corrosion inhibitor.

For most iron pipes, rods, and equipment, this kind of external protection is wondrous as it enables a corrosive barrier and rightly presents the anti-rust packaging. At the same time, this rust-free packaging is capable of being used in many pieces of machinery, metal spare parts, iron alloy products, vehicles, automobile parts, storage tanks for energy-based resources, and so on.

Therefore, the industries that utilize the rust-free packaging include Aerospace and Military, Automotive, Energy renewable, Energy Oil and Gas, Manufacturing heavy equipment and machinery, and so on. Another sector where anti-rust packaging is quite prevalent today is the Export sector where various machine parts, metal segments, and such metal-based materials are exported. For the same rust-free export packaging is the best option and it ensures that all the materials being exported are delivered in the exact condition while improving the longevity.

Technologies supporting Rust-Free Export Packaging

Zavenir Daubert is working diligently in solving the corrosion issue. We have developed many technologies based on which products are manufactured and corrosion problems are solved through preventive methods. Rust-free packaging is one such solution. The technologies that form the base of anti-rust packaging are:

1. Daubert VCI Technology

It is based on the concept of Volatility & Polarity. Volatile ‘V’ Components are added to Corrosion Inhibiting ‘CI” Components. The VCI molecules align on the surface of the metal to a depth of 3-5 molecules. This layer of molecules, passivates the surface and creates a barrier that prevents oxidation. VCI allows transparent rust-free export packaging to prevent corrosion and remain intact for years to come while maintaining the quality of the original metal part.

2. Daubert VCI Multilayer Technology

This consists of three layers. The first layer restricts the moisture and lowers its transmission to the metal surface. The second layer protects the surface from damage with its strength. The third layer which contains the VCI, releases the corrosion preventive VCI molecules towards the metal surface to protect from corrosion. This is the best solution for rust-free export packaging.

3. Daubert VCI Desiccant Technology

In this, Daubert Desiccant-cum-VCI-Emitter absorb the moisture in the enclosed surface and release the VCI molecules that form a passivating layer on the metal surface to protect from corrosion in the anti-corrosive packaging.

After careful considerations, these technologies have been invented and the products discovered to carry out the applications for the same in real-life situations

Read Also: Protective Coating To Prevent Corrosion

Products that support Rust Free Packaging

There are products developed by Zavenir Daubert that work on the principles of the Anti-Corrosive Packaging technology above. These products are:

1. Daubert VCI Papers

Available in the form of papers that work on the Daubert VCI technology to provide protection against corrosion for up to 3 years as per the packaging design.

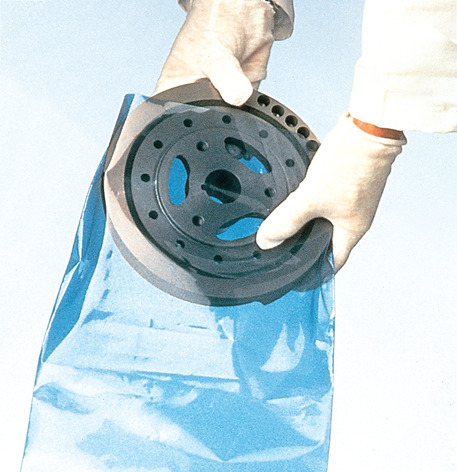

2. Daubert VCI Films

VCI and multilayer technologies work together in the form of VCI films to provide corrosion protection for up to 2 years depends on the packaging design.

3. Daubert NF VCI Emitter Cum Desiccant

Through the use of moisture absorbents or desiccants and with the added protection of Daubert VCI technology for anti-corrosive packaging, these products enable thorough corrosion prevention within enclosures.

4. Daubert 5 VCI Emitters

Works best on the metal surfaces exposed in enclosures by forming a passivating layer through volatility and polarity for protection against corrosion.

5. Daubert MPI Foam

A packaging option that provides rust-free packaging as well as cushioning of electronics and other sensitive substances. Works based on VCI Technology and is very lightweight.

Zavenir Daubert’s Rust Free Packaging Initiative

Having been in this field for a long time, the professionals of the Zavenir Daubert organization have gained tremendous exposure and experience and handled all kinds of challenges pertaining to corrosion protection through anti-rust packaging. Be it for internal use in a nation or for the export procedures, all the metal-based corrosive vulnerable commodities are backed with Daubert technologies for their rust-free export packaging.

All the products are readily available for use in any industry for the purpose of anti-corrosive packaging. If in any scenario a client is unable to take the right decision on the product and technology that can be best suited for their commodities, our Zavenir Daubert customer representatives are best versed in all situations. They can help you with their expertise by looking at the situation and suggesting the right solution for maximum benefit. Our services are customizable and personalized in order to especially look at any situation personally before making the right decision.

There are times when more than one technology is suited for a commodity, In that case, what should be done is decided by the experts from the Zavenir Daubert panel ensuring greater customer satisfaction.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)