April 2023

April 2023What is VCI Foam and How Does it Work for Corrosion Prevention?

VCI Foam is an innovative and effective solution for preventing corrosion in various industries. Corrosion is a serious issue that affects a wide range of products, components, and equipment, resulting in expensive repairs, downtime, and safety hazards. VCI Foam is a type of foam that releases Volatile Corrosion Inhibitors (VCIs) to create a protective layer around the metal surface, preventing corrosion and extending the lifespan of the product. In this article, we will explore the usage, application, and benefits of VCI Foam for corrosion prevention.

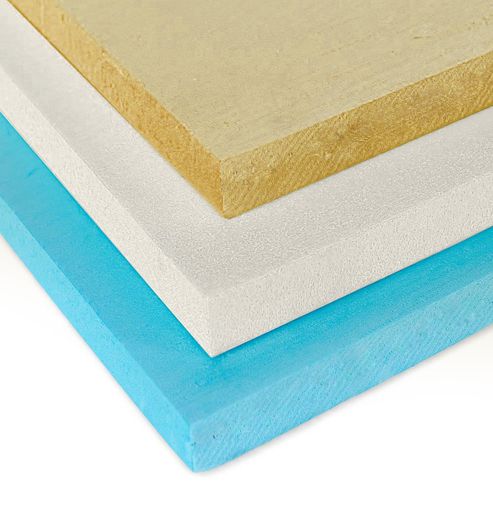

What is VCI Foam?

VCI foam is a specially designed foam that contains vapor corrosion inhibitors. These inhibitors are chemical compounds that have the ability to neutralize the corrosive gases and moisture that can cause corrosion on metals. The foam is designed to be easy to use and can be easily cut and shaped to fit around any metal object that needs to be protected from corrosion.

What is the usage or application of VCI Foam?

VCI foam is commonly used in a variety of industries, including automotive, aerospace, military, electronics, and industrial manufacturing. It is used to protect metal parts, equipment, and machinery during storage, shipping, and handling. VCI foam can be used for both short-term and long-term storage, making it an ideal solution for protecting metal components during transportation or when they are not in use.

VCI foam can be used as a standalone solution or in combination with other corrosion protection methods, such as VCI films or rust preventive oils. VCI foam can be used to protect a wide range of metal surfaces, including ferrous and non-ferrous metals, and it does not leave any residue or marks on the metal surface after use. Some of the common applications of VCI Foam are:

Protection of metal components during shipping and storage: VCI Foam is an excellent solution for protecting metal components during transit and storage. The foam can be cut into custom shapes to fit the product, providing a snug fit and maximum protection against corrosion.

Corrosion prevention of electrical and electronic equipment: VCI Foam is also used to protect electrical and electronic equipment, such as circuit boards, from corrosion. The foam can be placed inside the equipment or used as a packaging material to prevent moisture and humidity from damaging the sensitive components.

Preservation of military equipment: VCI Foam is widely used by the military to preserve their equipment during long-term storage. The foam provides a protective layer around the metal surface, preventing corrosion and ensuring that the equipment is ready for use when needed.

Read Also : How Rust Inhibitor Oil Works to Prevent Corrosion of Metal Surfaces?

How Does VCI Foam Works for Corrosion Prevention?

VCI Foam works by releasing Volatile Corrosion Inhibitors (VCIs) that form a protective layer around the metal surface. When the foam comes into contact with the metal, the VCIs vaporize and migrate to the surface, forming a thin layer of protection. The VCIs work by adsorbing onto the metal surface, creating a barrier that prevents moisture, oxygen, and other corrosive elements from reaching the metal surface.

VCI Foam is an effective solution for corrosion prevention because it provides continuous protection to the metal surface. Unlike traditional coatings, which can wear off or become damaged over time, VCI Foam releases VCIs as long as it is in contact with the metal surface. This means that even if the foam is damaged, the metal surface will still be protected by the VCIs that have been adsorbed onto it.

Zavenir Daubert VCI Foam - Key Features and Benefits:

Zavenir Daubert VCI foam is a high-quality VCI foam that provides superior protection against corrosion. Here are some key features and benefits of Zavenir Daubert VCI foam:

Multi-metal protection: Zavenir Daubert VCI foam can be used to protect a wide range of metal surfaces, including ferrous and non-ferrous metals. It is effective against all types of corrosion, including rust, tarnish, and staining.

Long-term protection: Zavenir Daubert VCI foam provides long-term protection against corrosion, making it an ideal solution for metal components that need corrosion protection.

Easy to use: Zavenir Daubert VCI foam is easy to use and can be easily cut and shaped to fit around any metal object that needs to be protected. It can be used as a standalone solution or in combination with other corrosion protection methods, such as VCI films or rust preventive oils.

Non-toxic: The VCI compounds used in Zavenir Daubert VCI foam are non-toxic and do not pose any health risks to users. This makes it a safe and environmentally friendly option for corrosion prevention.

Cost-effective: Zavenir Daubert VCI foam is a cost-effective solution for corrosion prevention. It helps to extend the lifespan of metal components, reducing the need for costly repairs and replacements.

Versatile: Zavenir Daubert VCI foam can be used in a variety of industries, including automotive, aerospace, military, electronics, and industrial manufacturing. It is suitable for both short-term and long-term storage, making it an ideal solution for protecting metal components during transportation or when they are not in use.

Non-abrasive: Zavenir Daubert VCI foam is non-abrasive and does not damage the metal surface in any way. It does not leave any residue or marks on the metal surface after use, making it a clean and convenient option for corrosion prevention.

Read Also : The Science Behind Corrosion Prevention of Metals: Understanding the Process

Leading VCI Foam Manufacturer

Zavenir Daubert is a leading VCI foam manufacturer that specializes in providing high-quality VCI Foam solutions for corrosion prevention and protection. Zavenir Daubert has been in the business of manufacturing VCI foam for years and has a proven track record of delivering innovative and effective solutions to its customers. Our VCI foam is a high-quality product that offers a range of key features and benefits, including multi-metal protection, long-term protection, ease of use, non-toxicity, cost-effectiveness, versatility, and non-abrasiveness. By using VCI foam such as Zavenir Daubert VCI foam, industries can significantly reduce the risk of corrosion-related damage and extend the lifespan of their valuable equipment and infrastructure.

By Mudit Mathur

(Senior Manager, Product Management & Marketing)