NOX-RUST®COATINGS

NOX-RUST®COATINGS

NOX-RUST®COATINGS

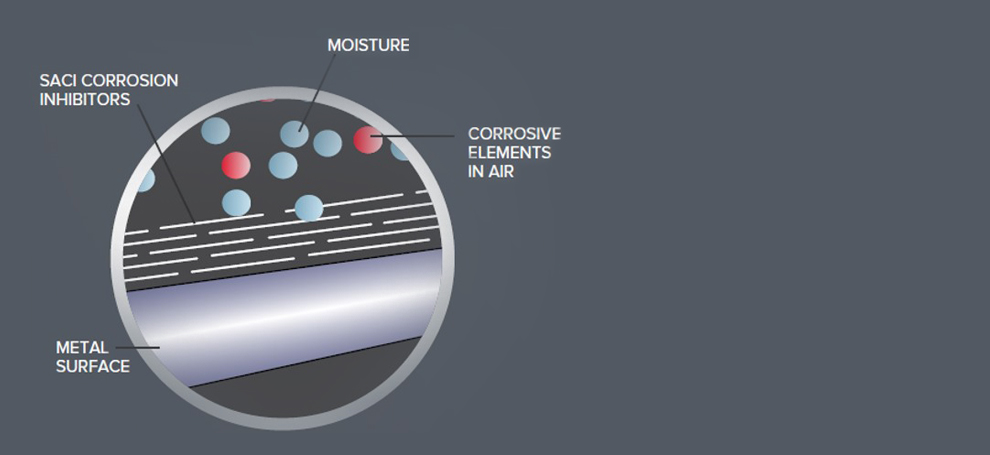

NOX-RUST® rust preventive coating is based on the SACI® Technology, which provides superior outdoor exterior corrosion protection during lay-up & mothballing. These products have approvals from the leading global Oil & Gas players. Also, meet or exceed various international specifications, including the US Military MIL Specs with listings on numerous QPLs (Qualified Product Listings) of the US Department of Defence.

| Benefits | Advantages | Technology Features |

|---|---|---|

|

Reduce CPC (Cost Per component) |

Provide extended product life, improved operating costs, lower maintenance and reduced service expense Quick restarting of operations, ease of removal |

SACI Technology Removal by petroleum solvents, alkali or emulsion cleaners |

| Improve EHS |

Availability of environment friendly VOC free and water-based options |

Wide range of specialty products |

|

Improve Corrosion Protection |

Excellent rust protection in severe climates in outdoor conditions. From 6 months to 2 years Fast curing & sag resistant film Compatible with non-ferrous metal & lubricating oils Wide range of film types. Film thickness easily controlled |

SACI Technology, excellent salt spray life Special additives Special additives Wide range of specialty coatings |

| Approvals |

US Military MIL Specs – QPL Listings of NOX-RUST® Coatings |

Military Specifications A-A-59295, MIL-C-62218-A, MIL-C-0083933, MIL-PRF-16173E & MIL-C-11796B |

Applications

- O&G equipment

- Windmill equipment

- Heavy Engineering equipment

- Fabricated parts & assemblies

- Primed or un-primed steel

- Ball and roller bearings

- Engine blocks, valves, gears, tool and dies, bushings, taps, chains and numerous other metal parts

Technology

SACI® TECHNOLOGY

Oil & gas, heavy engineering, railways, defence, and certain automotive parts & equipment need a long duration corrosion protecti Read More