NOX-RUST®LIQUIDS

NOX-RUST®LIQUIDS

NOX-RUST®LIQUIDS

NOX-RUST® rust preventive oils are based on the CCI (Contact Corrosion Inhibition) Technology, which provides excellent corrosion protection to part in areas of high humidity and temperature. These products have approvals of leading global OEMs & the US Military. The Daubert 360 service supports PPAP (trials, approvals) & troubleshooting at end-customer locations globally.

| Benefits | Advantages | Technology Features |

|---|---|---|

|

Reduce CPC (Cost Per component) |

Directly by very low oil consumption Directly by lower evaporation losses Directly by improved sump life Indirectly by high productivity.Quick drying properties |

Thin Film Technology - Lower viscosities, Higher coverage per liter Very low aromatic content, Higher flash point Strong demulsification Narrow boiling point range & precise flash point |

| Improve EHS |

Globally HSE approved products & Barium free versions Ease of removal |

GHS, REACH, RoHS, IMDS compliant Thin Film Technology |

|

Improve Corrosion Protection |

Excellent rust protection in severe conditions - in high humid & corrosive atmospheres while during in-process, shipment and storage (indoor or outdoor). From 1 month to 2 years Tack free film, Non-oil staining, good removability, good chemical synthesis. Wide range of film types. Excellent water displacing and fingerprint neutralizing properties |

CCI Technology, excellent salt spray/humidity chamber life Thin Film Technology Special additives |

|

Special Applications |

Barium Free, Enclosed area (VCI Oils), Long term outdoor protection, Protection in acidic environment, compatible with nonmetals (Rubber, plastic, painted surfaces), compatibility with fuels & other oils/lubes |

Wide range of specialty products |

Applications

By Spray, Dip or Brush for rust protection of

- Semi finished parts - Pressed parts / CKD parts in transit, unpainted auto and truck body sections during shipments, stampings, sheet metal components, Phosphate and black dyed products, Parts for cutting and polishing, forgings, castings, tubes, Fasteners

- Finished Parts – Springs, machine & hand tools, aviation parts, gear shafts, bearings, blades, gear parts, wire and high precision parts (both ferrous & non-ferrous) for domestic & export shipments

- Coils/Sheet - Cold rolled steel sheets & other Steel Mills applications

- Enclosed Area/Parts - fuel tanks, storage tanks, cylinders, transmissions, gear housings, clutch compartments, crankcases, hydraulic and cooling circulating systems

Technology

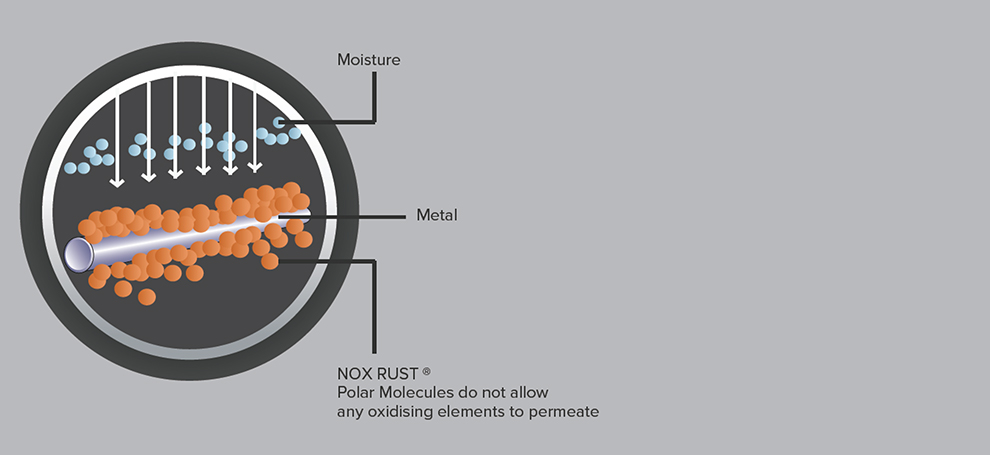

CCI TECHNOLOGY

Corrosion protection of parts is an important factor during WIP (work in progress), storage & shipping due to environmental factors l Read More