Parts & equipment cleaning is an integral and critical element of the value chain within many industrial manufacturing processes. Conventional cleaners with basic surfactant formulations are inefficient on non-polar and ionic contaminations. These cleaners leave residues (watermarks), cause foaming and have no or very poor corrosion protection. Harsh pH ranges are also unsafe for the workers & can cause surface defect on parts.

X-CLEAN™, based on Latest Surfactant Technology to strike a fine balance of ingredients, structure, and polar character of a cleaner to meet specific requirements of the industrial applications. This technology harnesses the abilities of multi-functional Power Surfactants (combinations of non-ionic and cationic surfactants) to deterge versatile organic & inorganic soils by reducing the surface tension by adsorption at the liquid-gas interface. This dynamism induces superb cleaning effect without compromising on the critical factors for industrial applications such as foaming where bubbles are rapidly generated and need to be stabilized. Corrosion prevention, biostability, pH buffer stability properties are introduced through the addition of various specialized additives specially designed to meet BS-VI emission standard’s requirements.

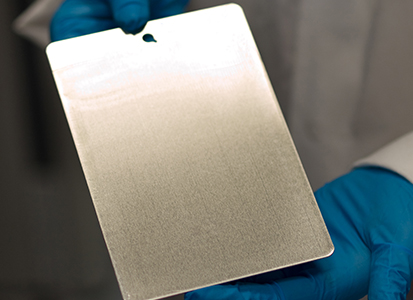

Special Combine Effect Action enables X-CLEAN™ cleaners to combine the power of emulsification (carrying off the soil/dirt from the components) & then demulsification (separating soil/dirt from cleaner to its surface for skimming) even at lower temperatures compared to conventional cleaners. This gives opportunities to substantially reduce the energy cost per component in parts cleaning.