CCI TECHNOLOGY

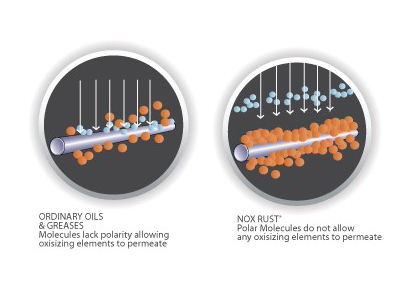

Corrosion protection of parts is an important factor during WIP (work in progress), storage & shipping due to environmental factors like humidity and temperature. Conventionally thick oils have been used to protect the parts but not so effectively. The barrier properties to prevent moisture & oxygen of such oils is poor due to dependence solely on weak cohesive intermolecular forces that hold a liquid together to itself and not the metal surface. The high viscosity results in high consumption, difficulty in removal & a tacky appearance.

Invented by George Daubert, Contact Corrosion Inhibition (CCI) technology is based on stronger adhesive intermolecular forces of the proprietary polar additives for superb rust protection even in tough conditions of high humidity and temperatures. The physical oil layer is thin as polar additives perform rust inhibition. This combination of adhesive Polarity & Thin Film Technology makes NOX-RUST® liquids form an impermeable layer for various corrosion causing elements like moisture & oxygen to attack the metal surface. The thin film due to low viscosity results in high coverage, low consumption, easy removal, significant cost & performance benefits.

Many vehicles are built with lightweight parts with hollow interiors, complex bends and welds which do not get adequate rust protection if water finds its way in from humidity, rain, puddles, etc. CCI Technology based, NOX-RUST® rust preventive waxes provide reliable protection, penetrating the tightest spaces with fast cure time. Also water-based low-VOC options provide peace-of-mind through compliance with strict occupational safety standards.

Daubert is the only leading global company which develops & manufacturers all additives itself.