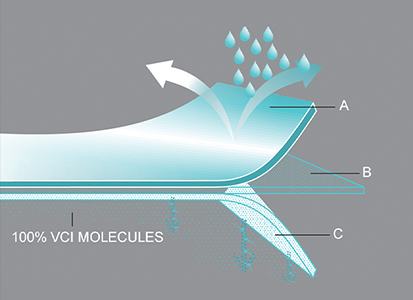

DAUBERT VCI® MULTILAYER TECHNOLOGY

VCI (Volatile Corrosion Inhibitors) film or VCI poly or VCI bag is increasingly becoming a popular choice of corrosion protection for exporters of metal parts due to various benefits like good strength & barrier properties, easy recyclability, transparency, branding & general wider acceptability. There are many cheaper versions of VCI polyethene in the form of monolayer films that provide only partial moisture-oxygen protection and have poor strength to carry heavy part loads. Also, the technical design of monolayer films has redundant bidirectional VCI release thus making them inefficient.

DAUBERT VCI® Multilayer Technology offers much better performance with VCI poly films like PREMIUM METAL-GUARD® & FERRO-FILM® than the other available VCI films or VCI bags in the market. There are three main components - 1. Moisture Barrier Layer - to restrict the ingress of moisture onto the components. This layer provides the film with a very low MVTR (Moisture Vapour Transmission Rate) / WTR (Water Transmission Rate) 2. High Strength Layer - to prevent any kind of damage (breaking or rupture) to the VCI film during loading, shipping, or unloading. This layer provides the film with a very high Dart Impact Strength 3. VCI Protection Layer - to protect the components from corrosion even in extreme conditions. This layer provides the VCI film with a very effective unidirectional (towards the metal surface to be protected) effective VCI molecules flow and action.