DAUBERT VCI® TECHNOLOGY

Packaging and maintenance of metal parts have always been cumbersome, owing to corrosion which to this day remains one of the major reasons to which product quality is severely compromised. VCI (Volatile Corrosion Inhibition) has found an indispensable place in applications in the industry for corrosion protection due to various benefits like ease of use and customizations availability. Simply pack the metal part to be protected in the VCI paper or VCI Film and parts remain corrosion-free for months and year to come without using any thick RP oils. But not all VCI are equal. Apart from the product quality, there are key technological differences.

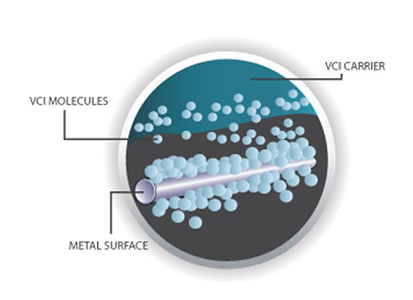

DAUBERT VCI® Technology was invented by Mr George Daubert in 1948. This technology is based on the concept of Volatility & Polarity and its ability to self-apply and dissipate. Daubert Volatile Corrosion Inhibition Technology involves the use of volatility (V) for the transport of corrosion inhibiting (CI) molecules from the carrier (paper, poly, foam or emitter), to protect the component from rusting by adsorbing on the metal surface and forming a thin passivating layer which inhibits the oxidation action of the surrounding environment. The Daubert VCI molecules align on the metal surface to a depth of 3-5 molecules. The reservoir of VCI in the carrier maintains the protective layer with a continuous flow of fresh molecules even as the charge of the molecules adsorbed on the metal surface depletes.

In Daubert VCI papers, this unique technology is effective on both ferrous (VAPOR WRAPPER®, PROTEK WRAP®, Q-WRAP®) and non-ferrous (UNIWRAP®, SILVER SAVER®, COPPERTEX®) metal surfaces. Other carrier variants are VCI plastic films (PREMIUM METAL-GUARD® and Ferro-Film®), foams (DAUBRITE® MPI FOAM), desiccates (DAUBRITE® NF VCI EMITTER CUM DESICCANT) & emitters (DAUBRITE® 5 VCI EMITTERS). The powerful polarity of these VCI molecules lets them migrate into recesses and hard to reach areas in even the most complex shapes. These VCI chemicals have good water solubility as well. As the water condensation occurs in a contained package, Daubert water-soluble VCI turns that water into a VCI solution to provide very long duration protection. A vacuum is not required in case of Daubert VCI bags and the overall packaging is designed to “breathe”. Thus, reducing the packaging costs.