DAUBERT VCI® DESICCANT TECHNOLOGY

Rusting is a phenomena caused by oxygen reacting with metal in the presence of moisture. There is a myth that adsorbing moisture alone in the enclosed space can prevent corrosion during storage and shipping. Hence, usage of hygroscopic substances (desiccants) such as silica gel, clay, and molecular sieves etc is prevalent. These conventional desiccants have no intrinsic corrosion protection & their moisture sorption capacity is a function of temperature. Such desiccants work well at ambient temperature but have decreased adsorption rate and equilibrium moisture content at higher temperatures. They aggravate the problem by releasing moisture back to the same closed environment when saturated with moisture and with the rise in temperature.

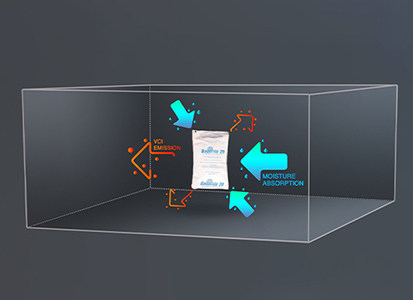

Both in storage and shipping, the daily cycles of temperature and humidity are common. Daubert has addressed the issue with DAUBRITE NF® a moisture absorbent combined with VCI molecules based on DAUBERT VCI® Desiccant Technology - a unique action of absorbing moisture and emitting VCI molecules in enclosed space. In the first step, desiccant action activates whenever the dew point is reached, and condensation starts to form inside the enclosed space. The moisture is adsorbed by the device up to even 200% of its weight compared to silica gel’s capacity of 40-50%. And in the second step during the rise in temperature, DAUBERT VCI® water-based molecules get released with the moisture. The VCI gets attracted to the metal surfaces and creates a passivating layer to prevent corrosion or rust.