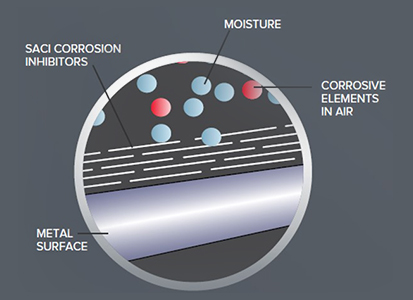

SACI® TECHNOLOGY

Oil & gas, heavy engineering, railways, defence, and certain automotive parts & equipment need a long duration corrosion protection in extreme outdoor open conditions of high temperature and high humidity. The major challenge is quick restoration after the lay-up period without environmentally friendly protection method. Thick oils & greases are not only difficult to apply and remove but also have no intrinsic rust protection properties. Other coatings popularly used are toxic with lead content in them.

Daubert SACI® (Severe Atmospheric Corrosion Inhibitor) Technology was developed based on the need to provide an environmentally responsible effective way of protection for metals from corrosion in adverse, exposed severe environmental condition. A structure of highly polar, overlapping microscopic platelets that effectively block moisture. Moisture & oxygen cannot penetrate to the metal surfaces even in severe harsh atmospheric conditions because of this impeccable barrier. Compared to other coatings, SACI® Technology & based NOX-RUST® coatings have high thermal stability, cracking/peeling resistance and fast hold on sharp edges. These products are lead and barium free & do not have the toxicity of traditional coatings.

Even barges, bearings, cables, engines, tanks, offshore rigs, and platforms operating within the harshest salt-water environments benefit greatly from products incorporating SACI® Technology for long term corrosion protection.