VCI Bags Manufacturer and Supplier - Shield Your Assets from corrosion

In the time of industries across India, keeping safe, valuable equipment, machinery, and components from corrosion is very important. This is where VCI (Volatile Corrosion Inhibitor) bags come in. Let's talk about the VCI bags, exploring their importance, applications, and benefits in preserving important metal parts from corrosion.

Understanding VCI Bags - A Layer of Protection

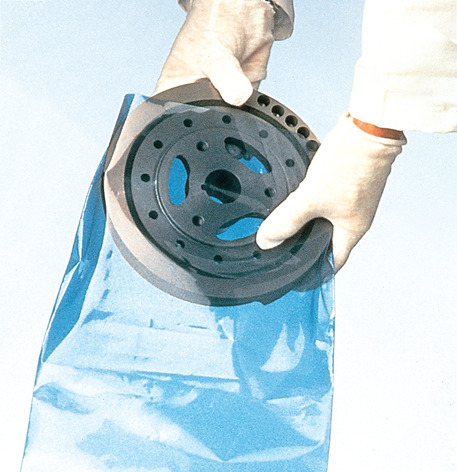

These Bags are designed to protect metals and alloys from corrosion. VCI bags use advanced technology that releases vapors, which form a protective layer around the enclosed item, preventing corrosion and oxidation.

VCI Bags Applications Across Industries

These bags find applications in a wide array of industries in India, including:

Automotive Sector : Shielding spare parts, engines, and components from rust during storage and transit.

Manufacturing

: Preserving machined parts, tools, and equipment before assembly.

Electronics

: Safeguarding delicate electronic components and circuitry.

Aerospace

: Protecting critical aerospace components from corrosion.

Heavy Machinery

: Ensuring longevity of heavy-duty equipment through extended storage periods.

Tailored Solutions for Diverse Needs - Customized VCI Bag Variants

VCI bags come in various forms to suit specific requirements:

Zip-lock VCI Bags

: Convenient resealable option for easy access.

Gusseted VCI Bags

: Designed to accommodate larger items or multiple components.

VCI Shrink Film

: Providing a snug fit for irregularly shaped items.

Benefits of VCI Bags Corrosion Protection

TheseI bags offer a host of advantages, including:Long-term Protection : Safeguards against corrosion for extended periods, reducing maintenance costs.

Non-toxic and Environmentally Friendly : This technology is safe for personnel and eco-friendly.

Cost-effective : Eliminates the need for expensive coatings or oils for corrosion prevention.

Easy Application : Requires minimal training for effective use.

Transparent Packaging : Allows easy identification of enclosed items.

Choosing the Right VCI Bag for Your Needs

In selecting VCI bags factors like material, size and intended use play a key role. Consult a reputable provider to ensure you get the best solution for your needs.

Safeguarding Industries equipment and parts with VCI Bags

It is important to protect your valuable machinery, equipment and components against corrosion in India's dynamic industrial landscape. VCI bags (Volatile Corrosion Inhibitor Bags) are the perfect solution. Take a look at the importance, applications and benefits of VCI bags in protecting important metal parts.

Trusted VCI Bags Suppliers and Manufacturers

To protect your important assets against the corrosive effects of time, selecting the right VCI bag supplier is always good. A select group of Indian industry leaders has emerged as a reliable source for high-quality Volatile Corrosion Inhibitor Bags. These suppliers have a good track record in providing VCI packaging demand tailored to meet the needs of different industries. These trusted suppliers provide good quality and ensure their bags meet or exceed industry standards. They offer an unrivaled corrosion protection. They have gained the trust of companies in industries such as automotive, electronics, aerospace and manufacturing through years of work. These bags are the top quality when it comes to protecting India's industrial assets. Their products offer peace of mind, unmatched protection, and good service.

FAQ's

1. What is a VCI bag and how does it work?

A VCI bag, or Volatile Corrosion Inhibitor bag, is a specialized packaging solution designed to protect metal and alloy components from corrosion. These bags contain a special formulation of volatile corrosion inhibitors that release vapor molecules, creating a protective layer around the enclosed items. This layer inhibits the oxidation process, effectively preventing rust and corrosion.

2. What industries benefit from using VCI bags?

VCI bags find applications across a wide range of industries. They are particularly beneficial for automotive, manufacturing, electronics, aerospace, and heavy machinery sectors.

3. Are VCI bags environmentally friendly?

Yes, VCI bags are considered environmentally friendly. The volatile corrosion inhibitors used in these bags are non-toxic and safe for personnel.

4. How long does the protection offered by VCI bags last?

The effectiveness of VCI bags depends on various factors, including the specific formulation used, the type of metal, and the storage conditions. In general, VCI bags provide long-term protection, often lasting several months or even years.